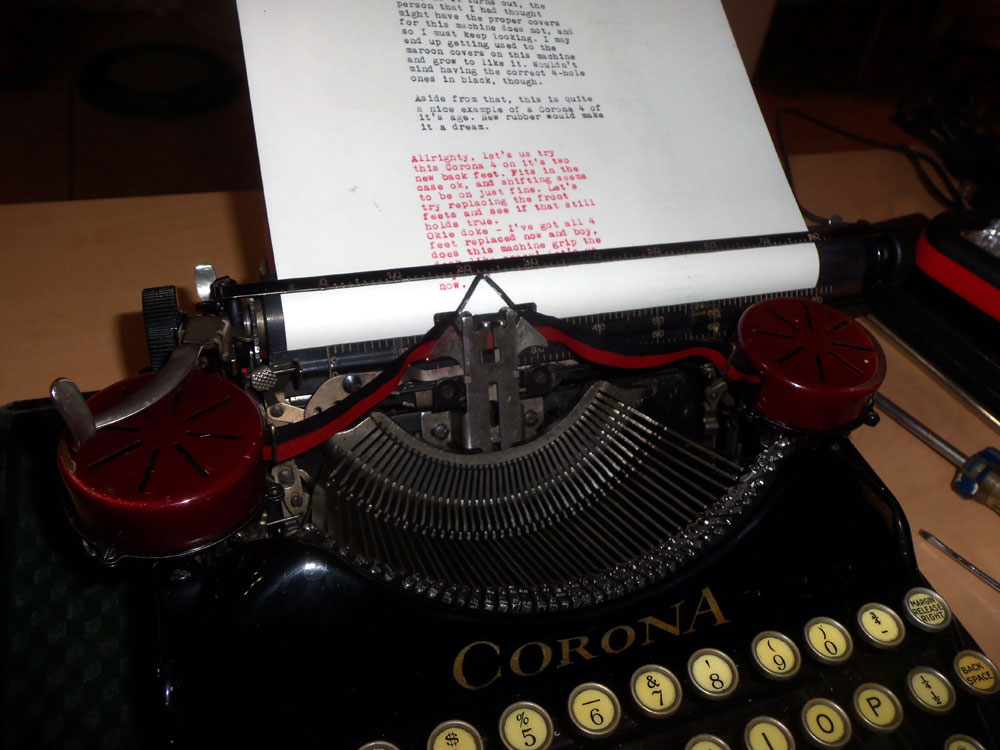

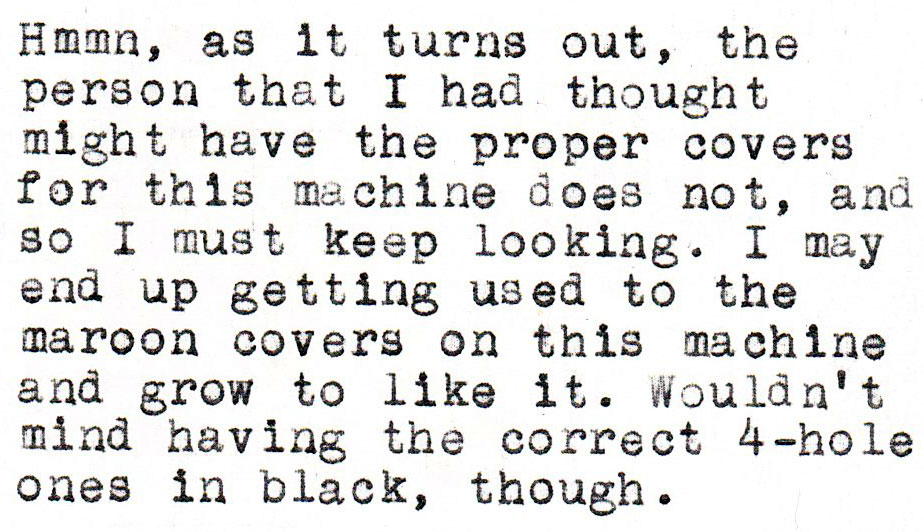

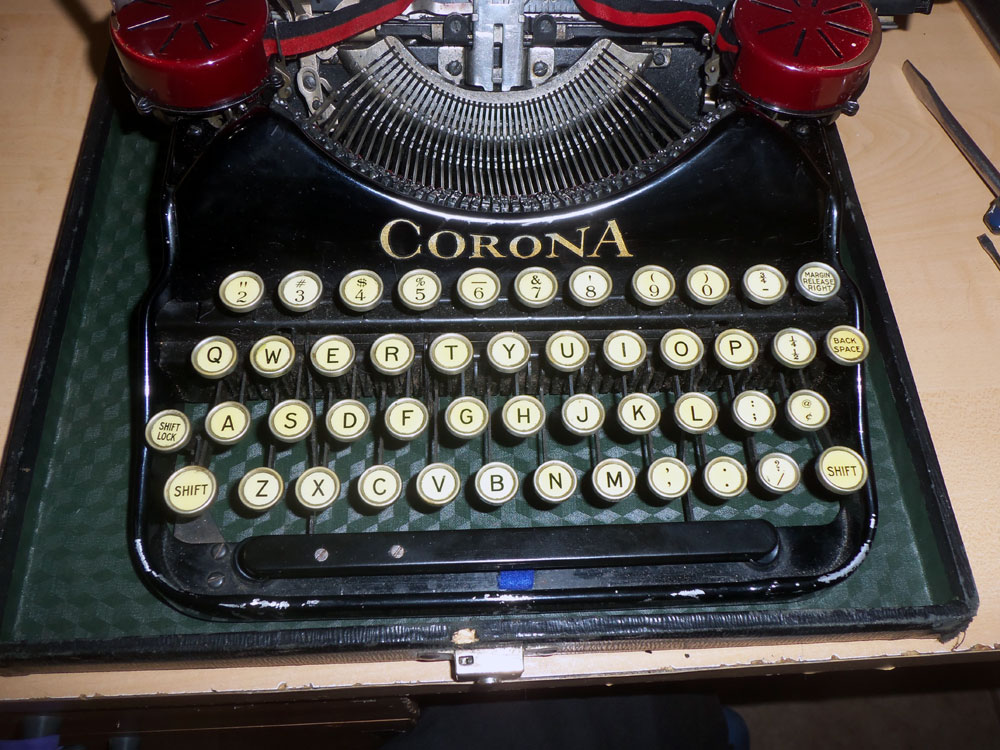

Weapon of Choice: “Richard The Deep Breather”, 1925 Corona 4.

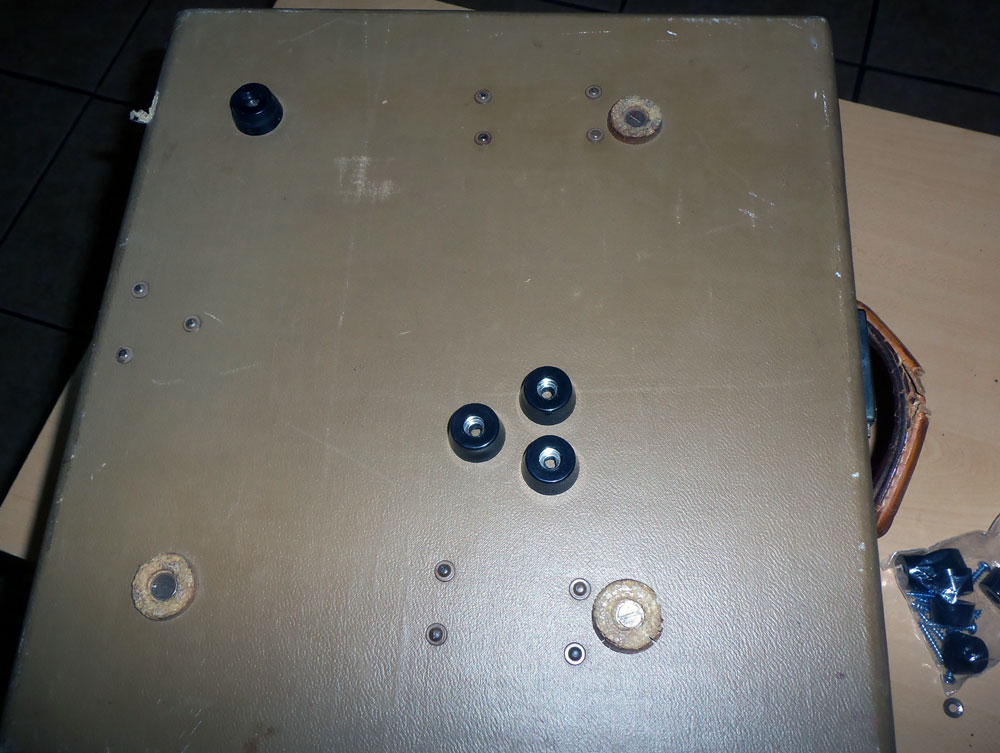

I found a bag of 4 sizes of rubber feet on amazon, 10 feet per size. I figured one of the sizes would be right for what I needed..

Chuck the foot into a drill and use a thin file to file a grove about halfway through the rubber.

The groove in the rubber slots into the C-shaped frame hole. The old, fossilized squashed feet just crumble off if you pry at them a little with a screwdriver.

Back feet on, and the top part sticks out just enough to cushion the last bit of travel of the shift mechanism, but does not impede the travel.

Same with the front feet – the rubber that sticks out the top is meant to cushion the last bit of travel of the space bar, but should not impede that travel.

Added some stickyback felt to the front hook in the case lid to keep it from scarring up the paint more than it has already..

While I’m fixing stuff, let’s re-orient the shift key label using the sharp points of a pair of scissors, as it was a bit crooked.

The case of my 1959 Consul 1511 needed new feet too. I used some of the larger ones for that..

Nice job.

I either order custom feet from Steve Dade or measure the more standard ones and get them From McMaster-Carr. I never gave Amazon a thought.

Nice new feetsies! I like your drill and file technique.

If you drill out the platen screw, take pictures. I have a similar platen set screw with a broken head and I just don’t know how to approach it without damaging the threads.

I will – I’m also pondering finding a nut that fits the head and try to wedge a driver in there good enough to get it to turn. I’ll keep posted (:

OK, Update on drilling out that screw – we ended up mangling the head of the old screw so badly that we decided to drill with no particular thought to ruining the old tapped threads in the platen rod, *but*, as soon as we stuck the drill in (with proper-sized bit), and applied power at high-torque, low-speed setting, the screw backed right out with minimal thread damage to the rod. I was able to take the same screw off a parts 1959 Tower President XII (silent-super clone) which had a better, fully formed head on it, and it screwed right in as a perfect replacement.

Well durn, I’ll have to try that foot filing method now. Such a simple yet effective idea. With some sand paper and a drill press, could probably fashion all sorts of feet styles.

Yar, once I got a look at how the original feet inserted into the frame, and how the top parts of the feet act as sort of shock absorbers for parts of the mechanism (or at least they did before they smooshed, shrunk and fossilized), the replacement seems fairly simple and obvious to construct. With a drill press, I expect you *could* fabricate even more complex shapes in rubber – I’d like to see results of some tries (: