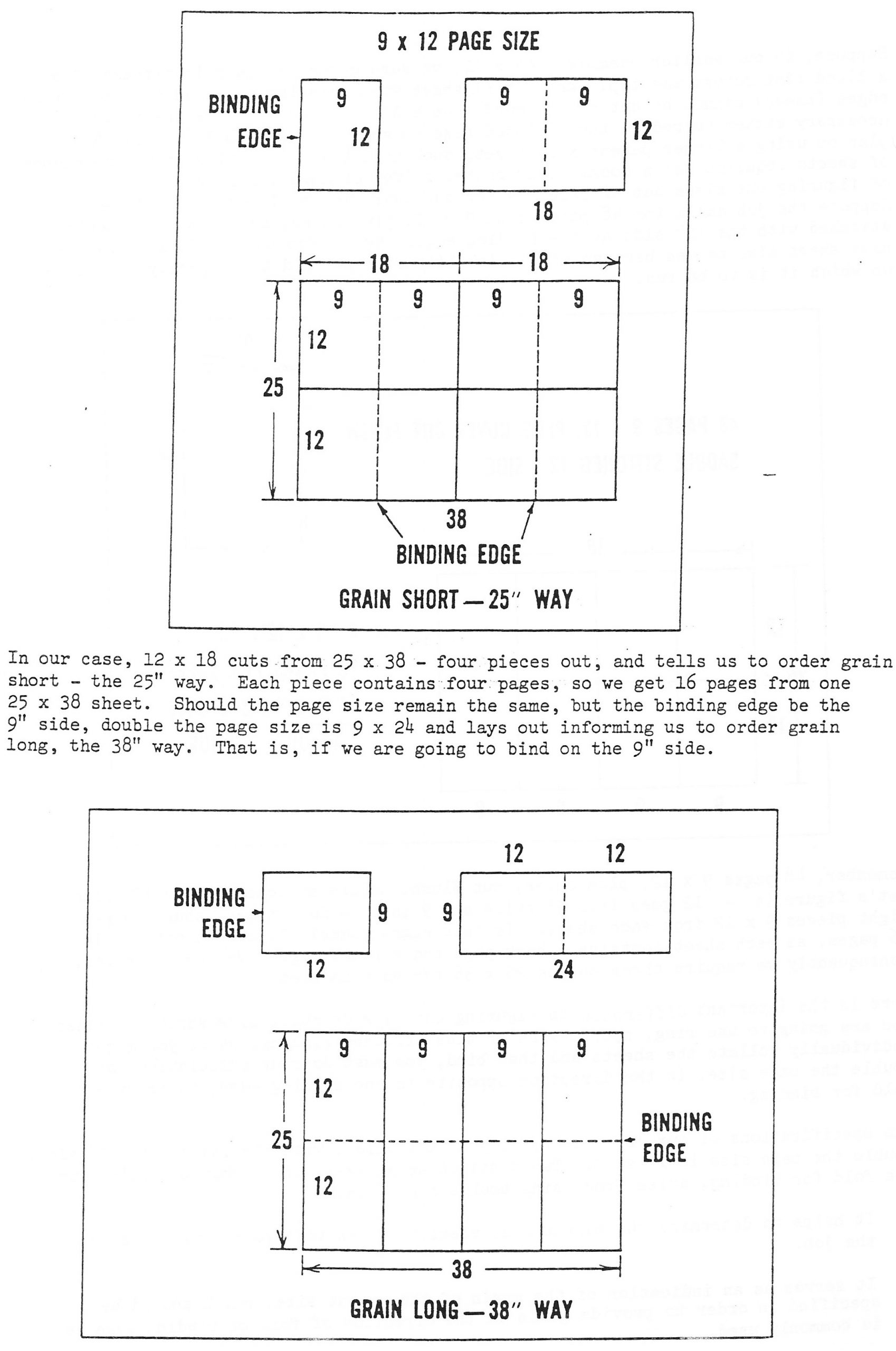

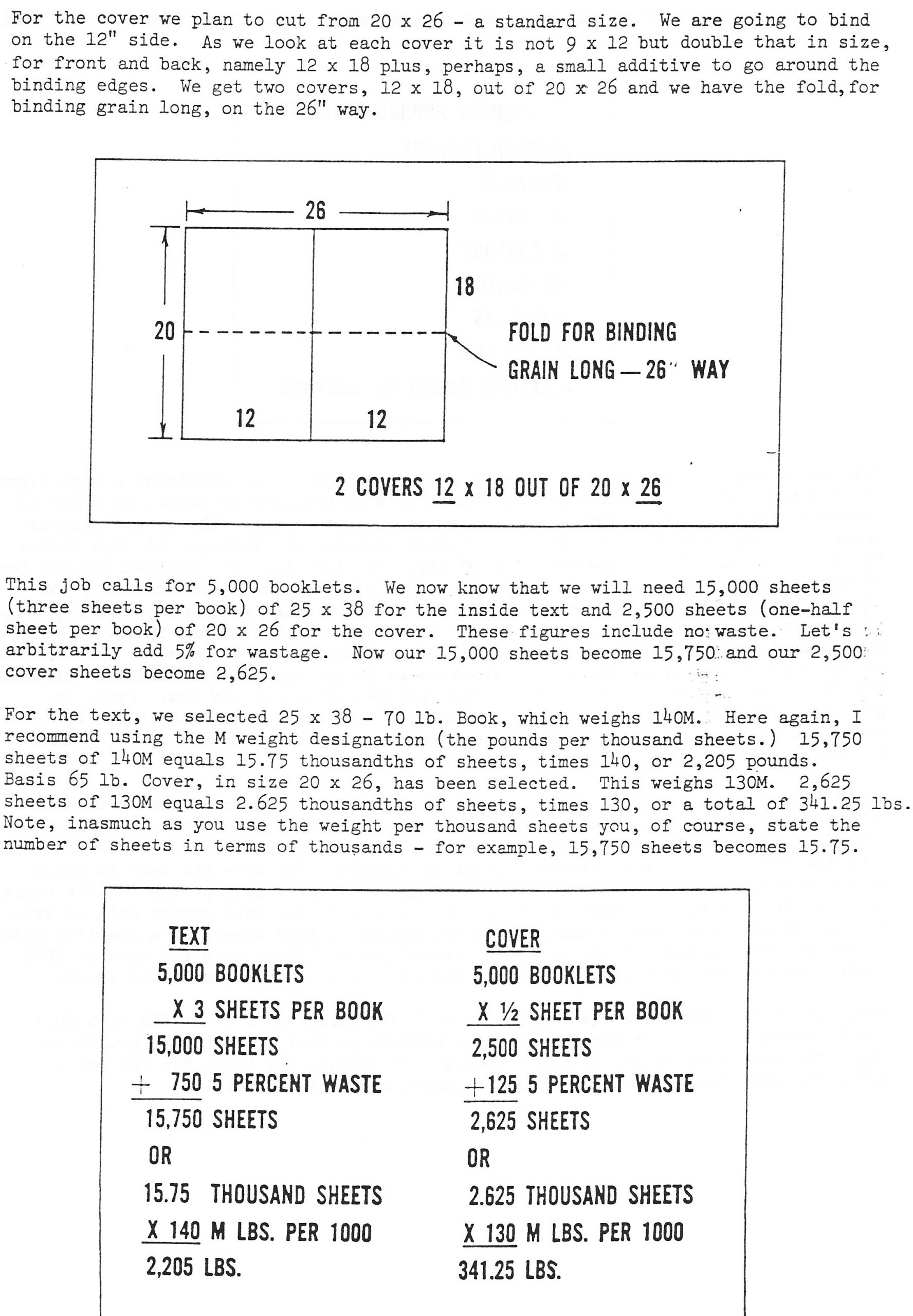

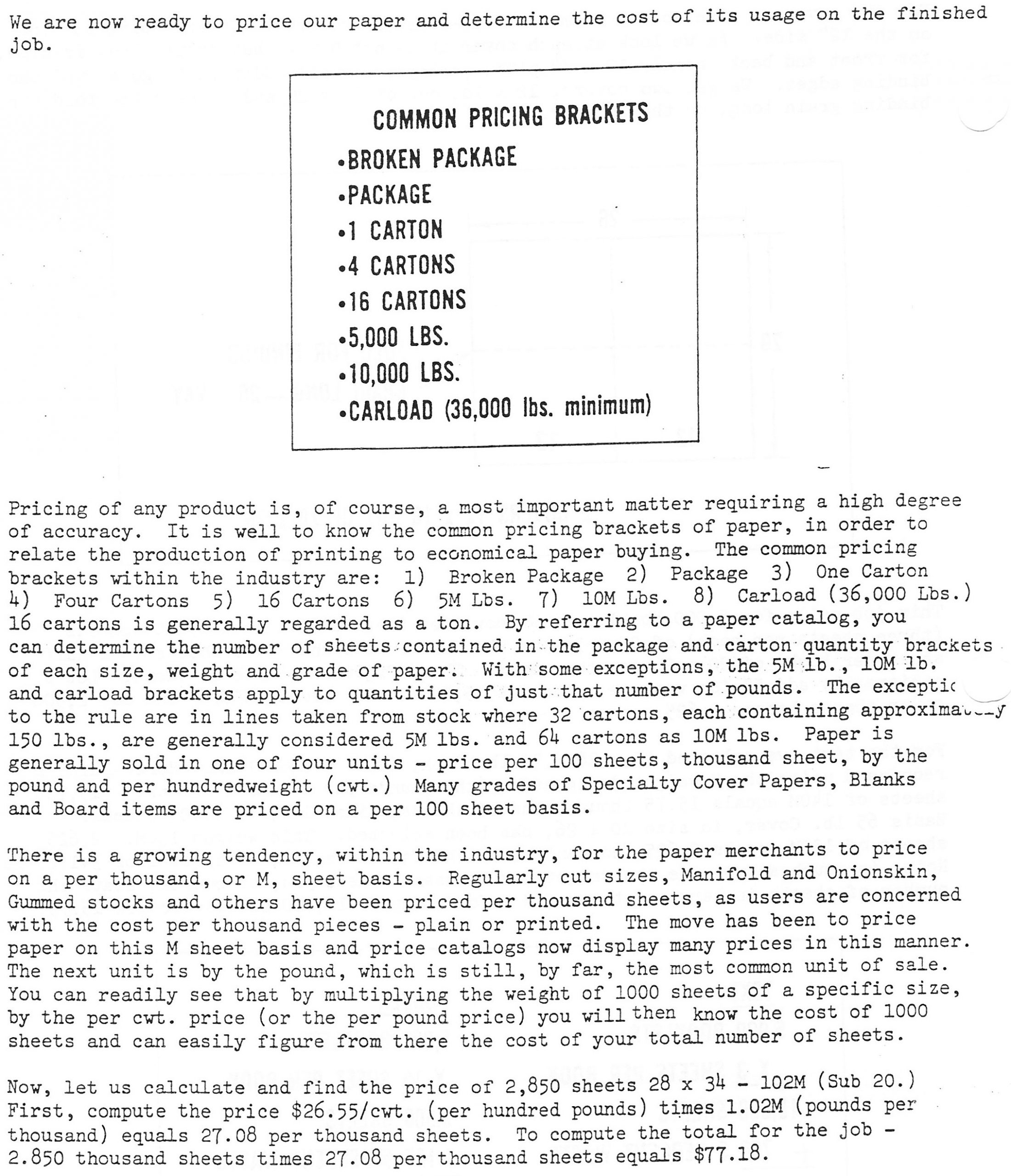

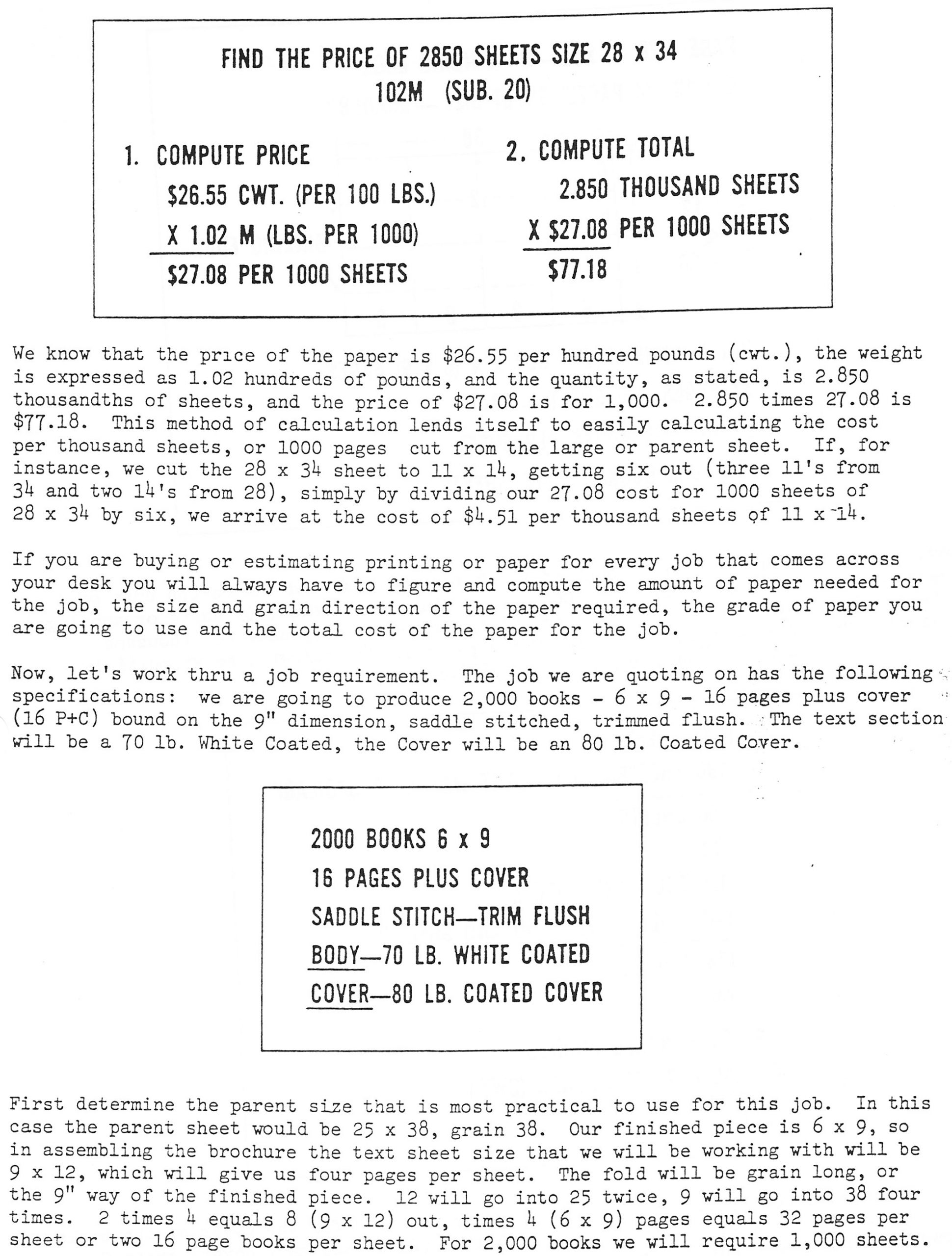

Boy, I’ll say that paging through this old binder has awoken a lot of memories for me, and this section on Paper Arithmetic reminded me of the first paper guillotine we had at the print shop – a quarter-ton cast iron 32″ full-manually operated Challenge from the 1920’s. Wrestling that beast to cut down parent sheets earned me a lot of muscle in my teens, as my thrifty-minded dad would buy pallets of remaindered parent stock from paper manufacturers so we could sell customers on weird colors and finishes for cheap flyers. We’d get all sorts of strange papers from check & bible stock to weird lenticular 3-D stocks and everything in between. All of it in parent sizes that needed to be cut down to a size we could run in the presses, so no larger than 12″ wide by 18″ long for the Itek, Ryobi and AB Dick “small” offset duplicators we had.

The big Challenge guillotine looked something like this. Big, heavy cast iron with a razor-sharp high-carbon blade.

The big Challenge guillotine looked something like this. Big, heavy cast iron with a razor-sharp high-carbon blade.

So, I got really good at “jogging” paper up to 30+ inches wide, which is no mean feat to learn. Paper that large is floppy like a giant wet noodle and doesn’t much want to line up with its neigbors, but you learn the trick of push-fanning air into the stack and dropping it onto the table while holding it loosely in both hands enough to let the sheets fall freely, but not so loose that they get away from you and spill all over the place. Once you master it with parent sheets, jogging a ream of 8.5×11″ paper is childs play. I can still hand-jog a loose ream of letter-sized paper perfectly square faster than you can drop it into an electromechanical jogging machine and flip the vibrator switch. Like riding a bicycle, it’s a skill that never goes away.

Examples of pebble-finish semi-coated paper and lenticular 3-D stocks. When really crazy stuff like this came in on remaindered pallets, I’d always steal some for printing stuff for my own projects, which is good because that meant I kept samples. :D

Examples of pebble-finish semi-coated paper and lenticular 3-D stocks. When really crazy stuff like this came in on remaindered pallets, I’d always steal some for printing stuff for my own projects, which is good because that meant I kept samples. :D

Eventually, we sold off the old Challenge guillotine and bought a shiny new pneumatically-operated one with synchronized buttons on either side of the paper table that had to be pressed simultaneously to drop the 25-pound razor-sharp cutting blade, so’s there was no chance you were gonna fire that thing off with your hand anywhere near the slicey bits. Supposedly safer than the hand-cranked Challenge, but realistically my 120 pound teenage body needed both hands on that counterweighted lever anyway just to get the blade through a half-ream of parent stock. Not really either more or less safe, TBH. Still, I had a healthy respect for paper guillotines and never ever wounded myself on one in near 25 years worth of working with them.

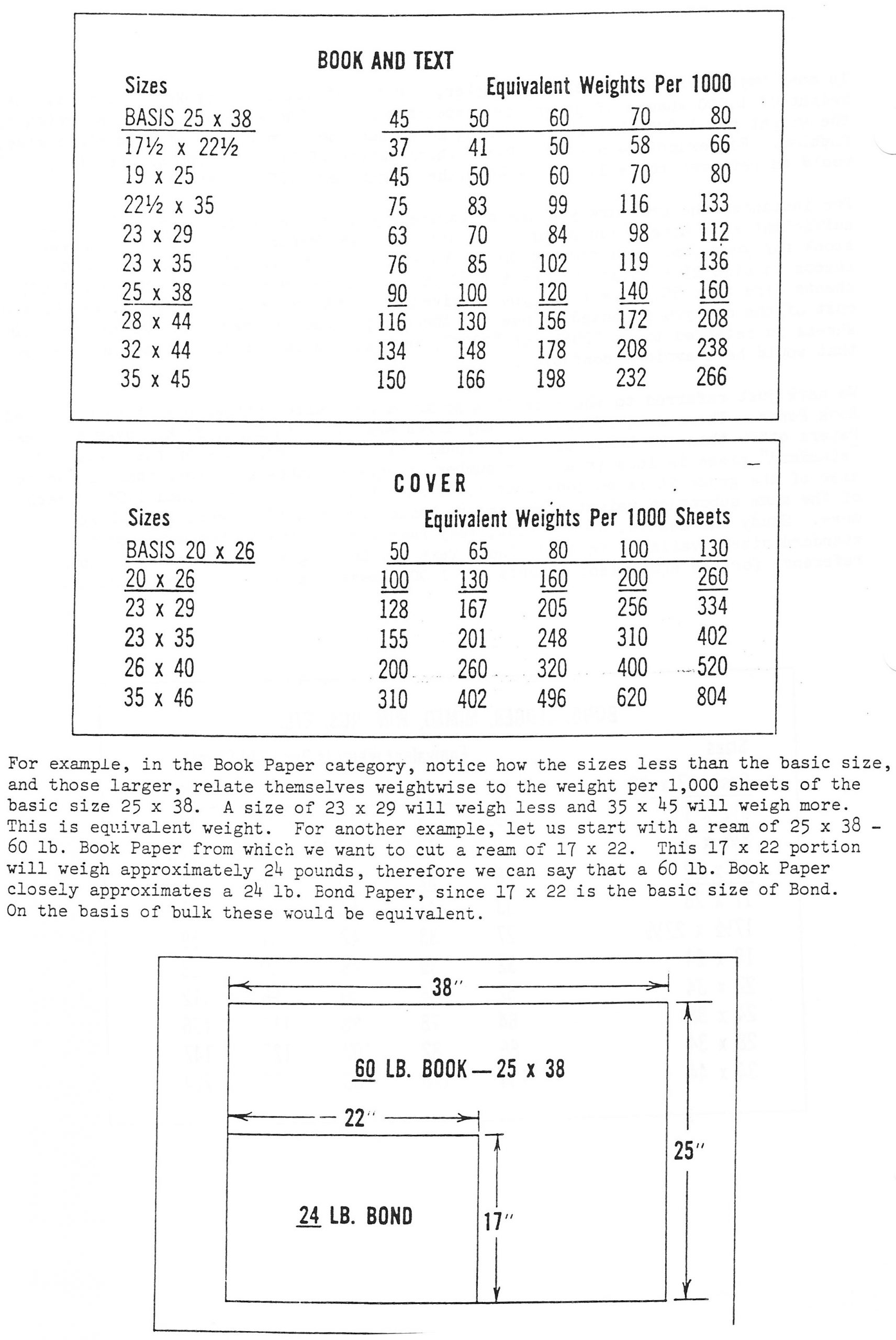

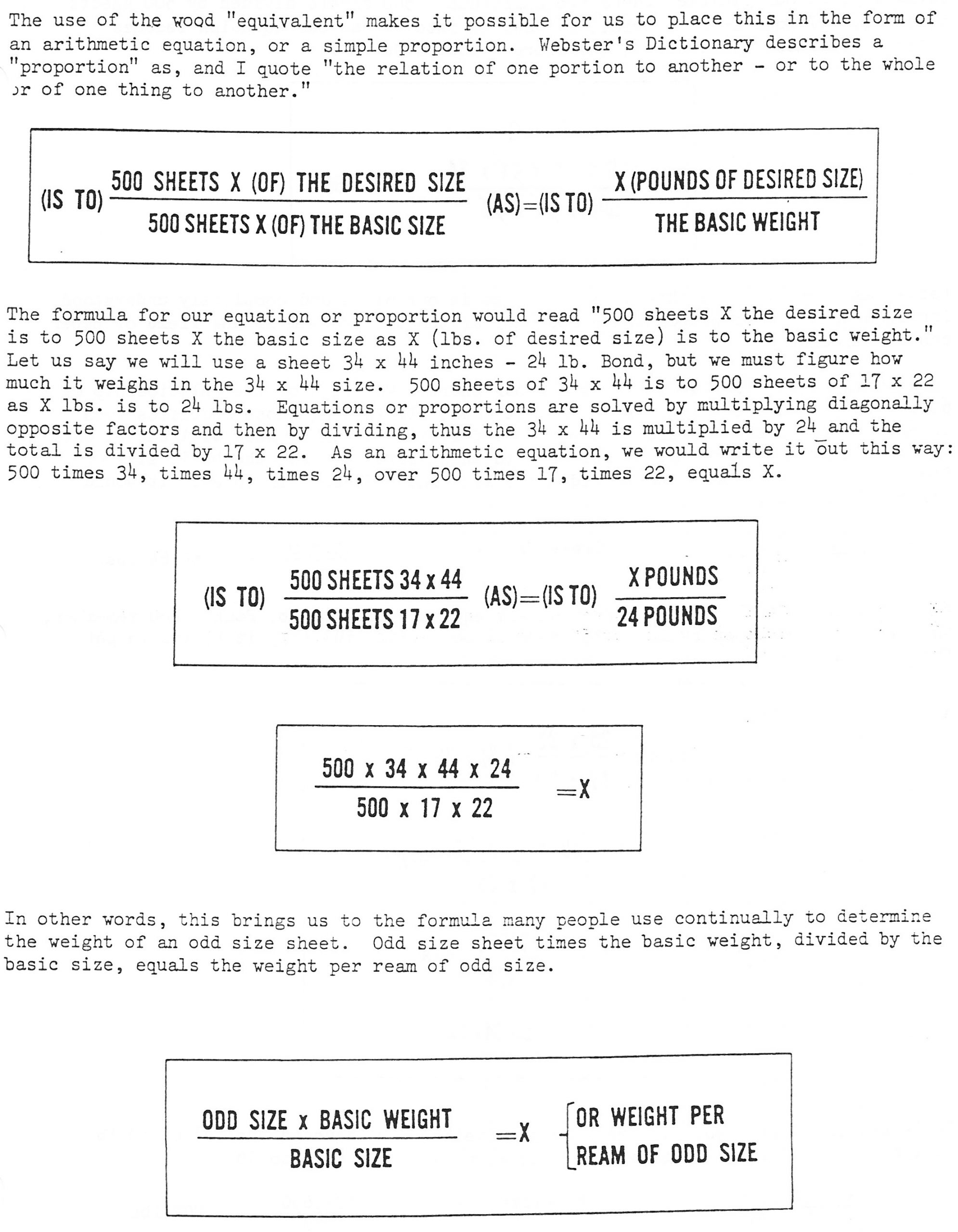

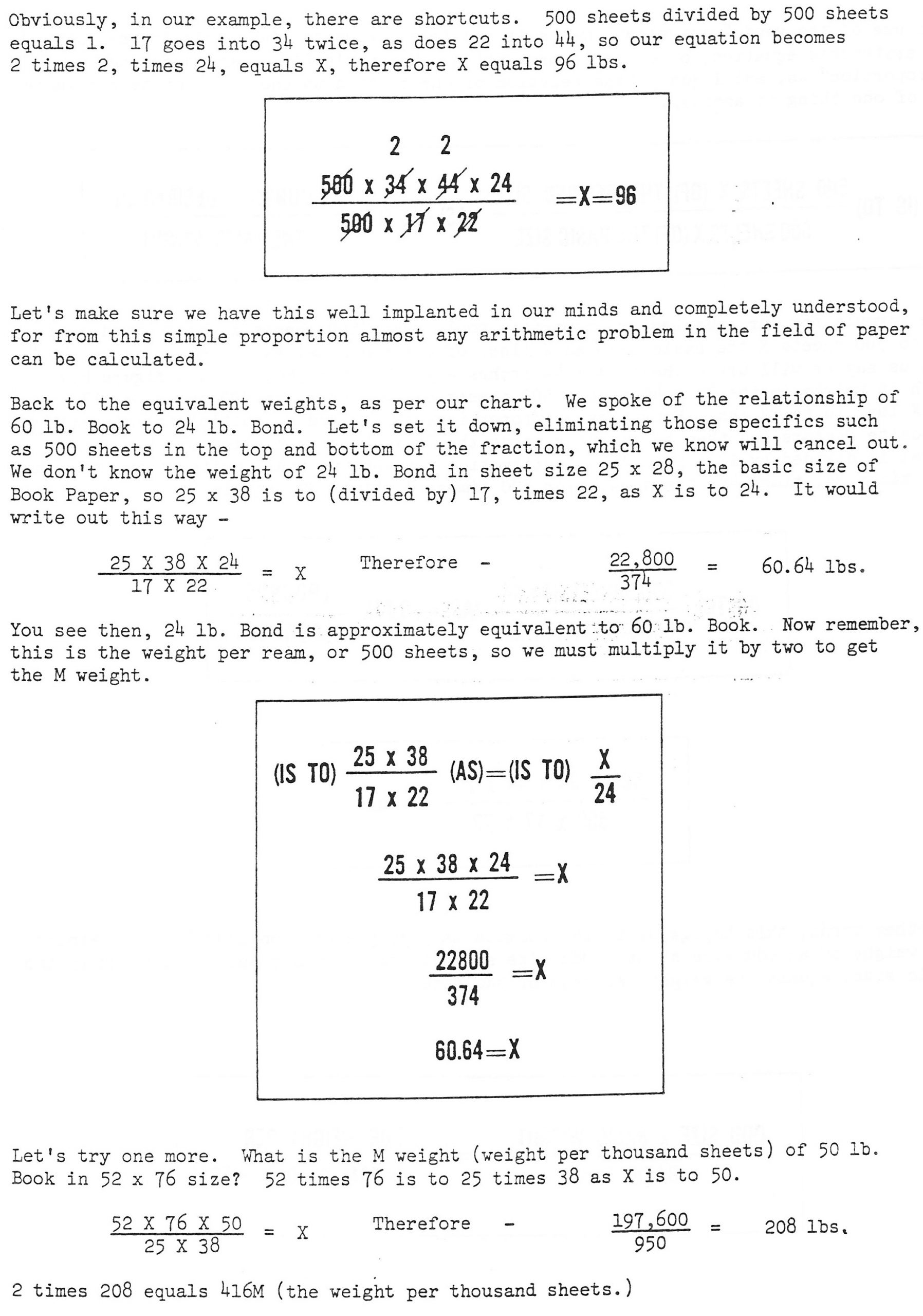

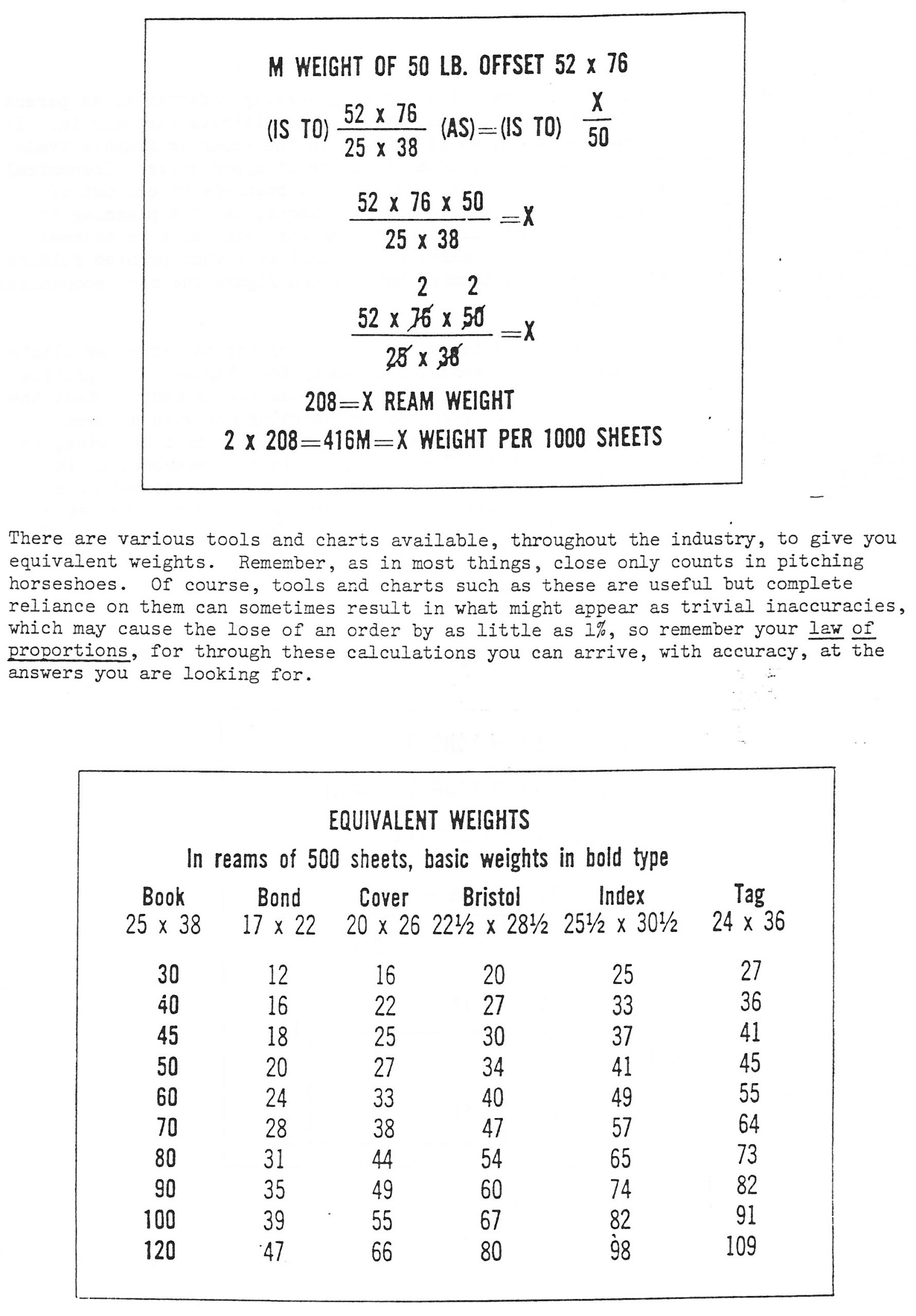

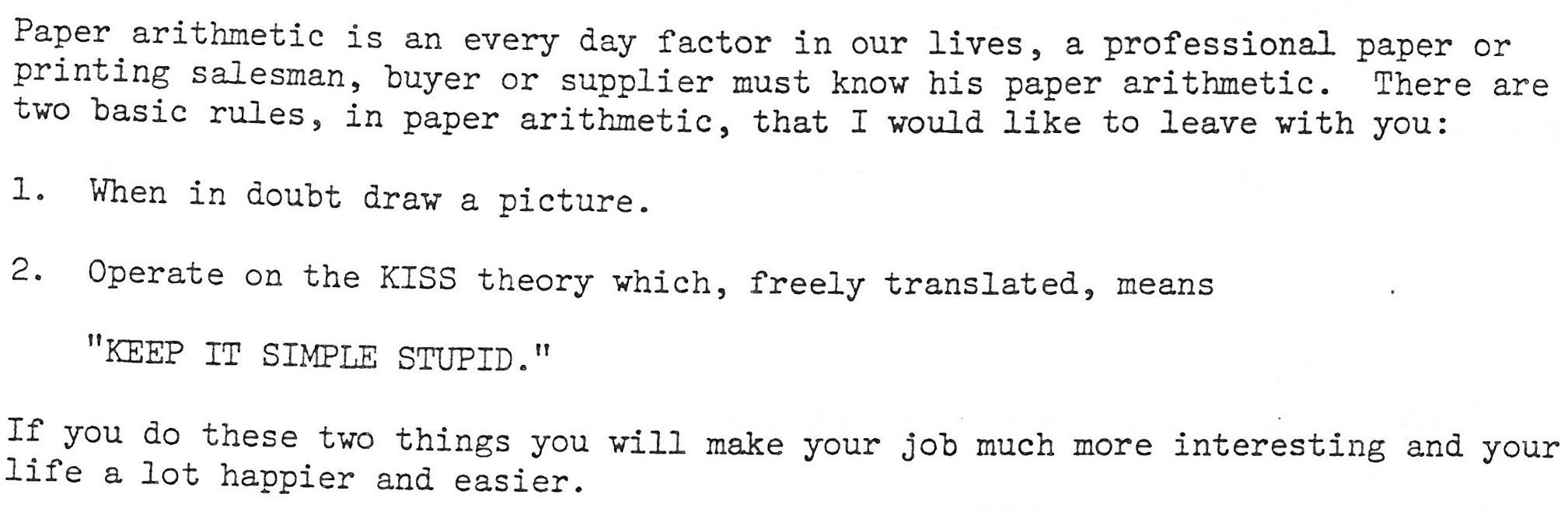

Anyway, Here’s a pretty in-depth explanation of paper-related calculating, and in Part 3 I’ll post some more condensed formulas. After that, we’ll get into terminology and if you’re still interested, I’ll post the primer on how various types of paper making processes work on an industrial scale – how finishes and watermarks are made in paper and all sorts of technobabble you might find interesting…

Ha, ha. Thanks for this 101 course. It shows why we civilians find paper specs so confusing. My father was in the paper business, and now I’m in the book design business explaining this to clients, so I have had a long yet mild experience with these intricacies. Your work here will be a valued reference for me.

Quite a wealth of information. Seems a lot of the parent sizes are based on an ANSI C sheet. I wonder why paper was not based on an ANSI D and cut to different sizes. Seems one parent size would have made things simpler unless a shop had the capacity to handle the large rolls. Then there are the hemungus rolls of paper the newspapers still use.

Thanks for posting all the interesting information, much of which I’ve first heard about from you post. I do remember those big old guillotine paper cutters though. We had one in the school print shop and where I first worked as an electronics engineer.

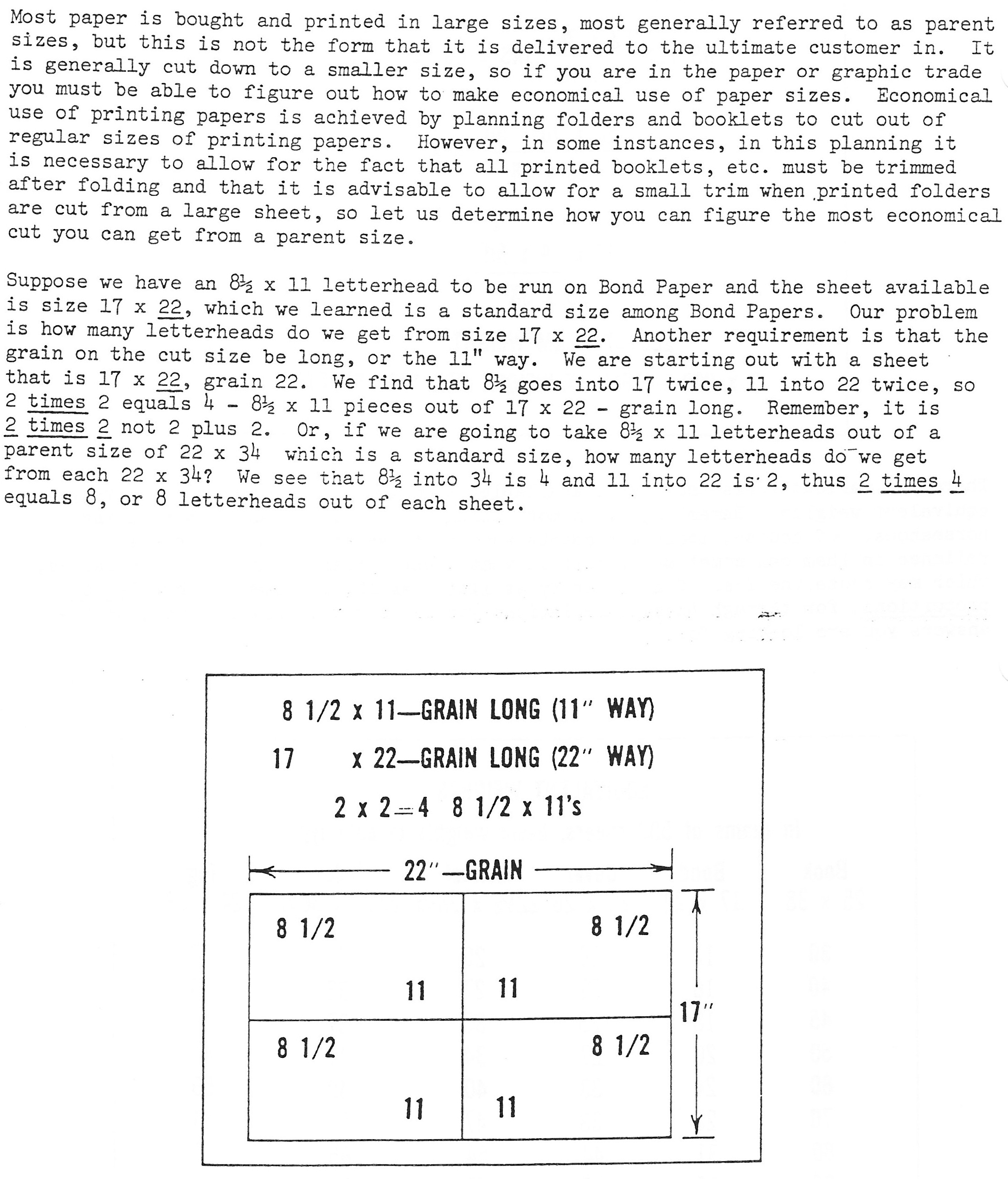

This is pretty intense stuff. But I’m stuck on the fact that I keep referring to the AB Dick 360 as a “press” (such as in my epic comment found in the previous post) even though you already gently corrected me that the AB Dick is a duplicator.

heh, well, it’s semantics really – but I wasn’t actually a “pressman” until I started running a Heidelberg GTO 52. :D

Wow. “Draw a picture and make sure.” Wise words, although making sure that you get the picture right would seem to be of great importance as well.

Whoa, this is intricate!

An entertaining read – glad to hear that you survived with all your fingers intact :) Wish my dad were still alive so I could share your Paper 101 series with him. He was a print hobbyist having caught the bug after working briefly for a printer in the 1940s. He had a collection of presses in his basement and was a driven and enthusiastic collector of flongs – which were very, very hard to find when he was alive. I see flongs by the zillions now on eBay.

Perhaps they are plentiful now that the inhabitants of the island of San Serriffe have been able to access the internets, and can now sell off their ancestral flonga. :D

:D!