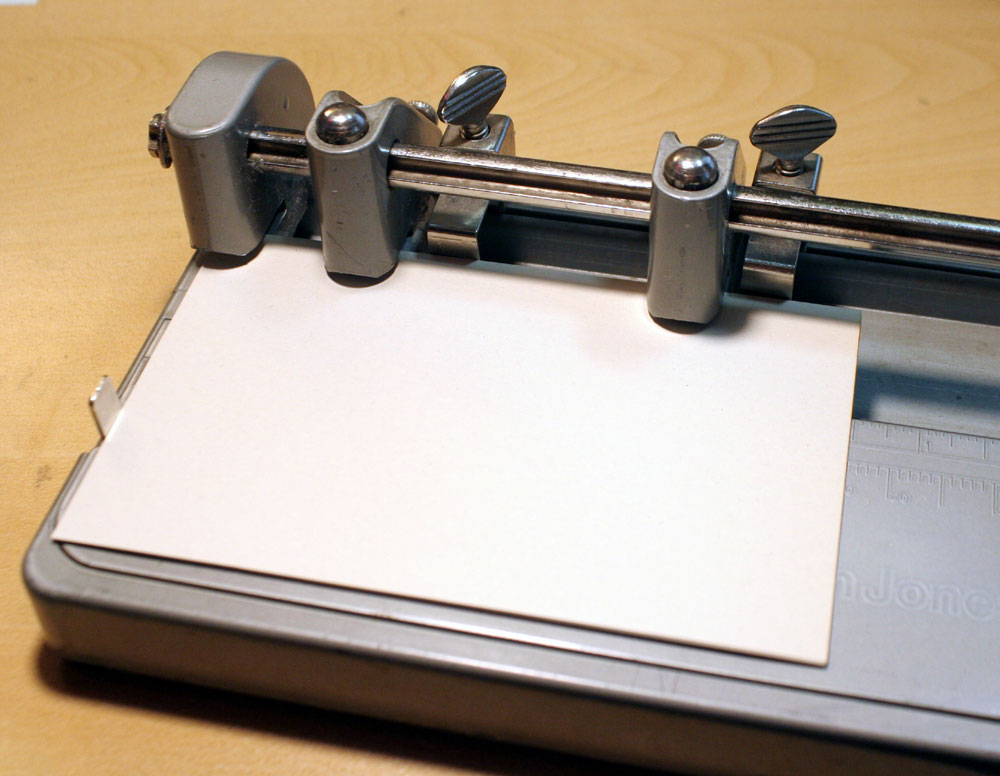

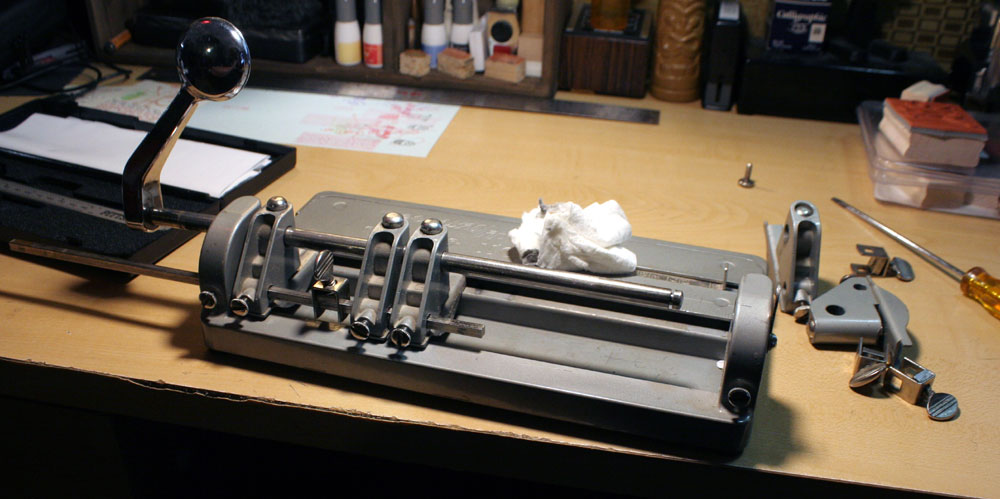

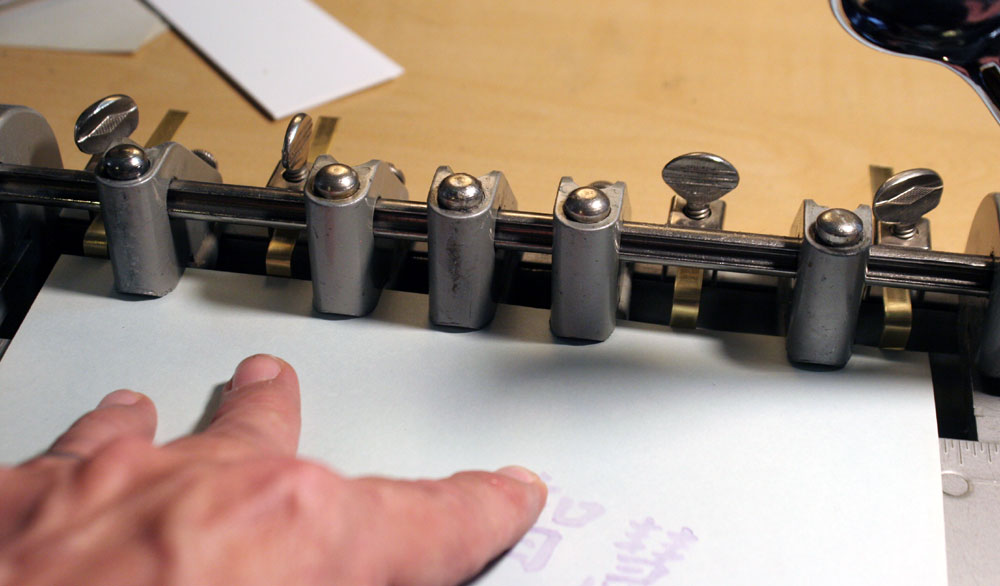

Weapon of Choice: newer Wilson-Jones Hummer set up as 2-Tower, 2-Backstop EDCN format puncher, Punching some new high-gloss KromeKote paper for EDCN testing…

Weapon of Choice: newer Wilson-Jones Hummer set up as 2-Tower, 2-Backstop EDCN format puncher, Punching some new high-gloss KromeKote paper for EDCN testing…

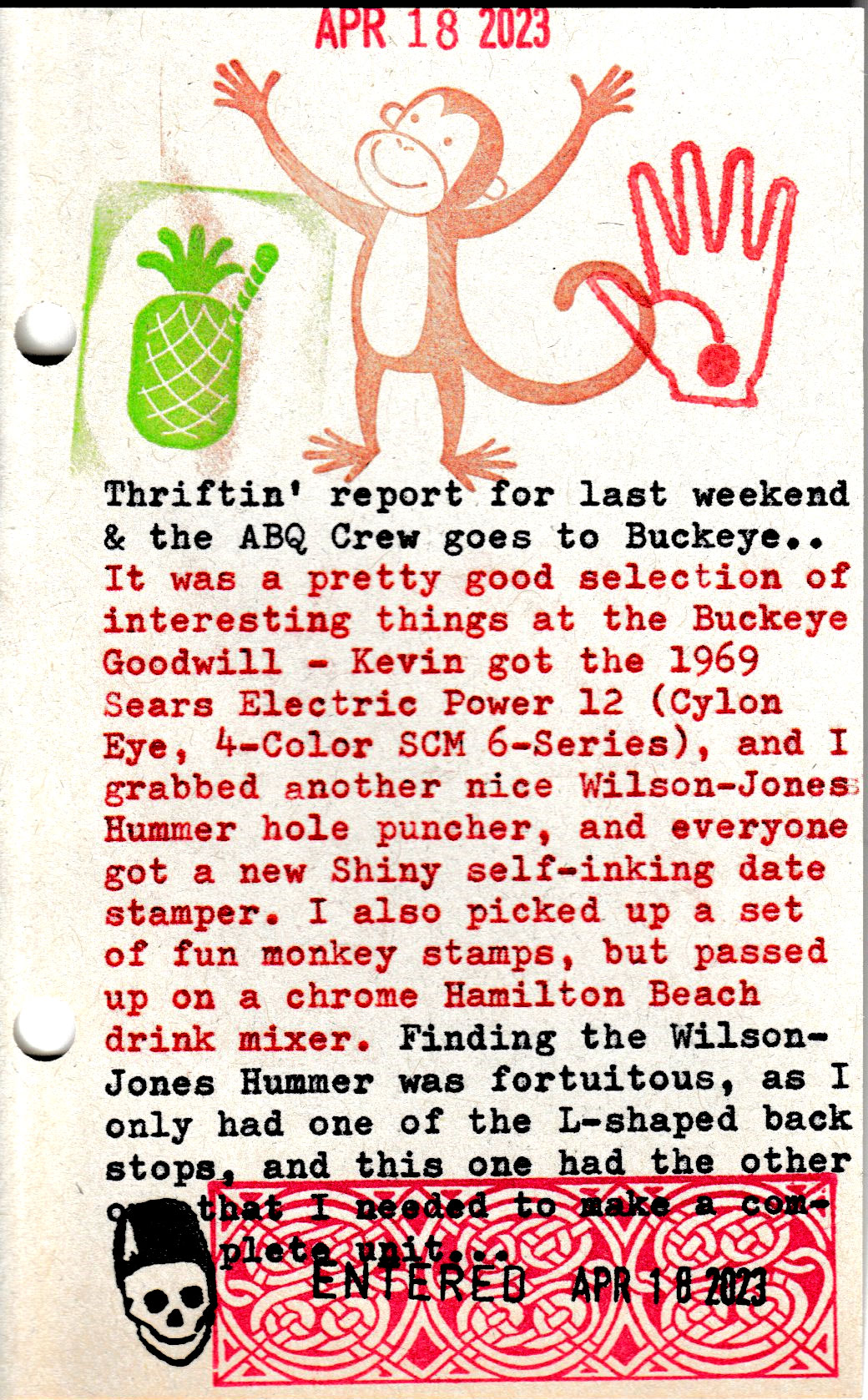

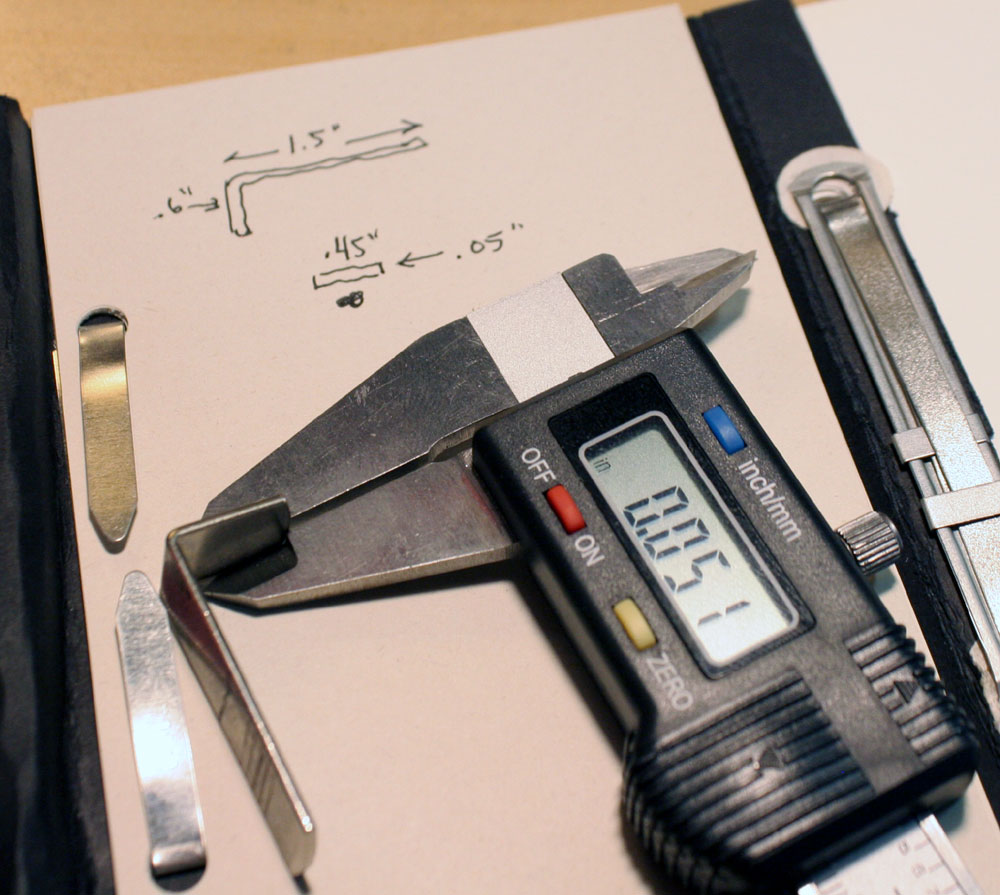

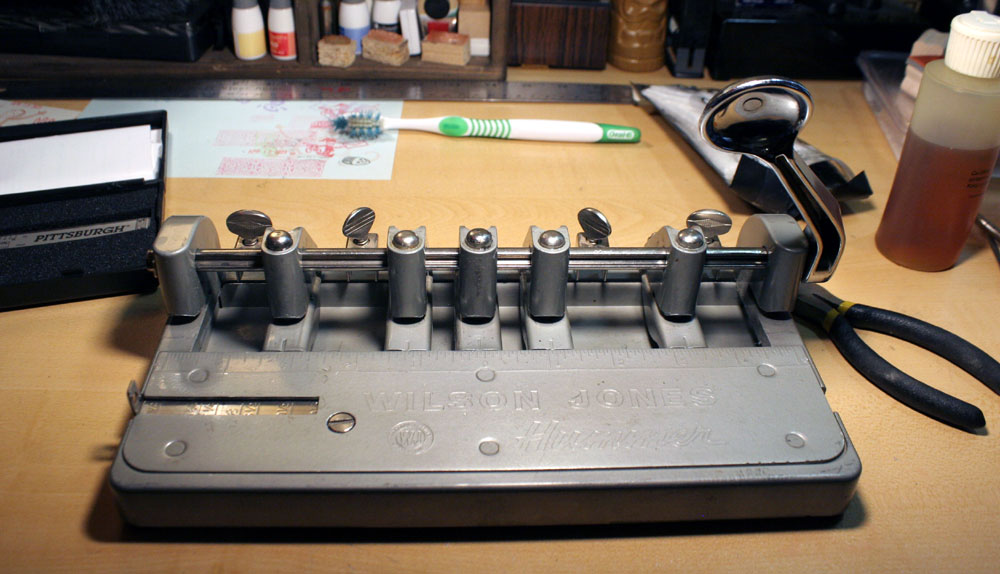

Now that I have one Hummer set up for EDCN use, I can combine parts from the two others to make another one. Unfortunately, I have no other original backstop brackets, but we’ll solve that problem later. No, Wilson-Jones no longer makes spares, and the backstops seem to be the most commonly-lost part for the Hummer, IMLE. Let’s spec out the original backstop and see if we can source a substitute.

Now that I have one Hummer set up for EDCN use, I can combine parts from the two others to make another one. Unfortunately, I have no other original backstop brackets, but we’ll solve that problem later. No, Wilson-Jones no longer makes spares, and the backstops seem to be the most commonly-lost part for the Hummer, IMLE. Let’s spec out the original backstop and see if we can source a substitute.  And while we’re at it, let’s take apart and clean/oil the old Hummers and combine the best parts into a 5-Tower, 4-Backstop Monster Hummer.

And while we’re at it, let’s take apart and clean/oil the old Hummers and combine the best parts into a 5-Tower, 4-Backstop Monster Hummer.

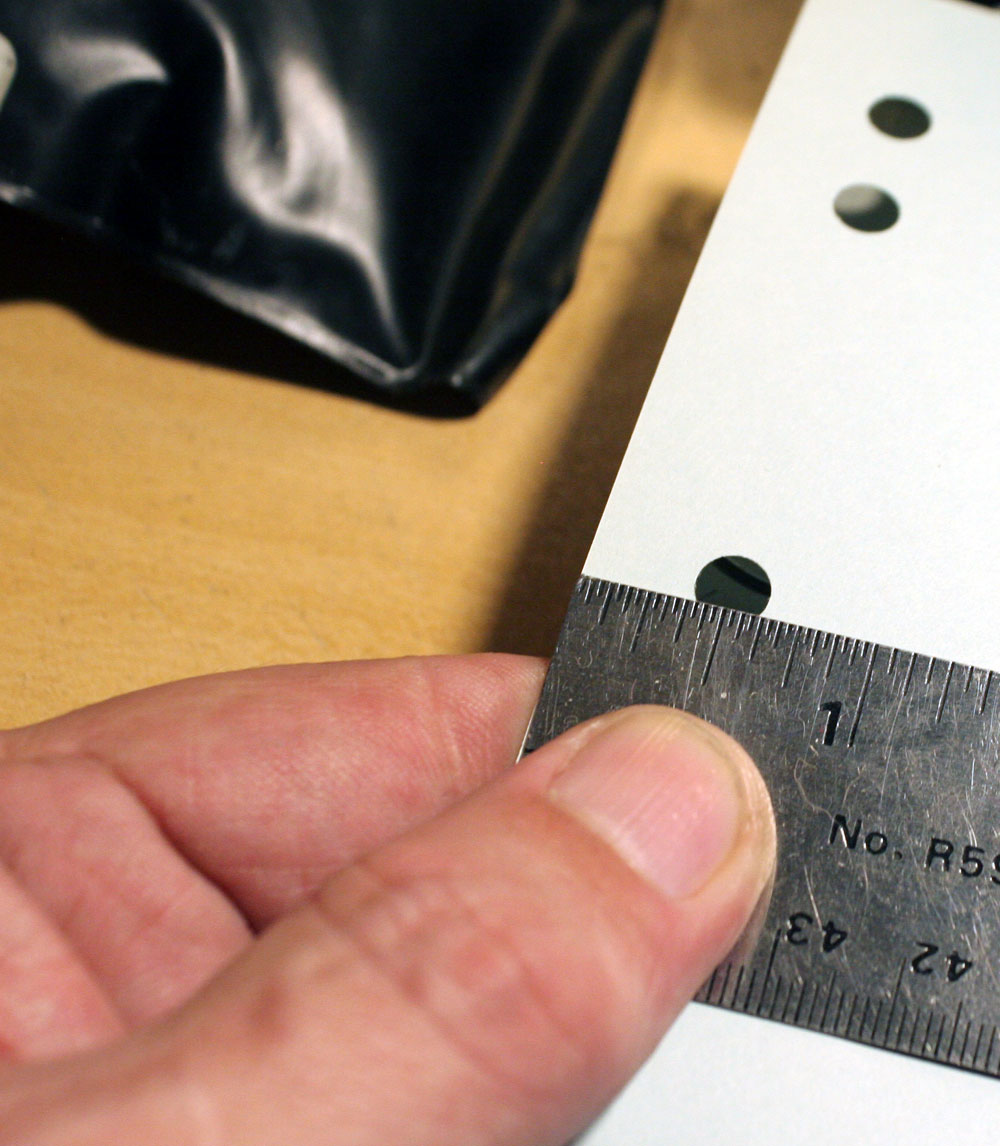

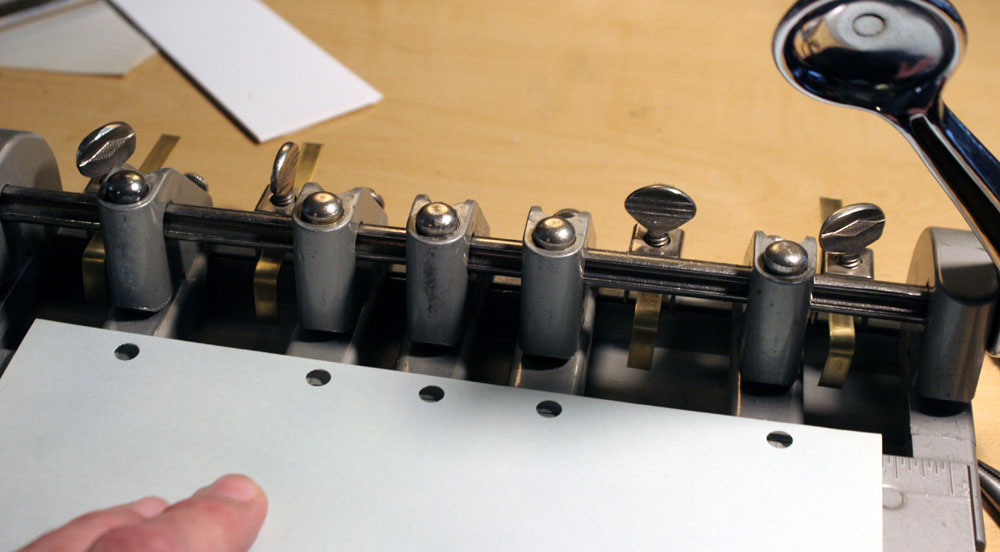

There are slight differences between the different machines that could be considered someday for dating purposes. One difference is the hole at the end of the base guide. Older ones have the hole, newer ones don’t.

There are slight differences between the different machines that could be considered someday for dating purposes. One difference is the hole at the end of the base guide. Older ones have the hole, newer ones don’t.

Cleaned and assembled, but still no backstoppers. Without backstops, the default depth of the punch will center the hole at 1/2″ into the page. The backstops allow you to set that depth shallower than 1/2″.

Cleaned and assembled, but still no backstoppers. Without backstops, the default depth of the punch will center the hole at 1/2″ into the page. The backstops allow you to set that depth shallower than 1/2″.  Hey look, these might work! :D

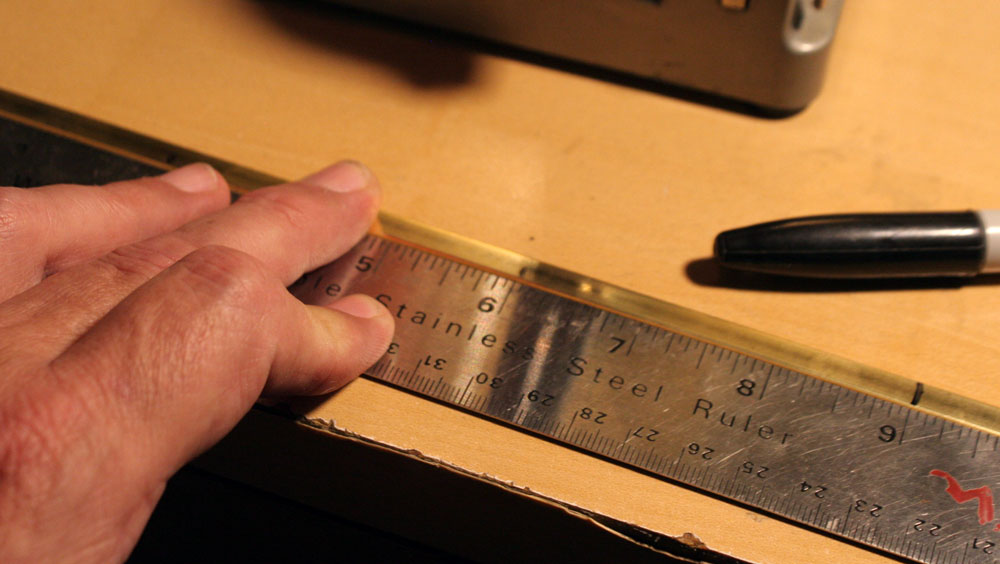

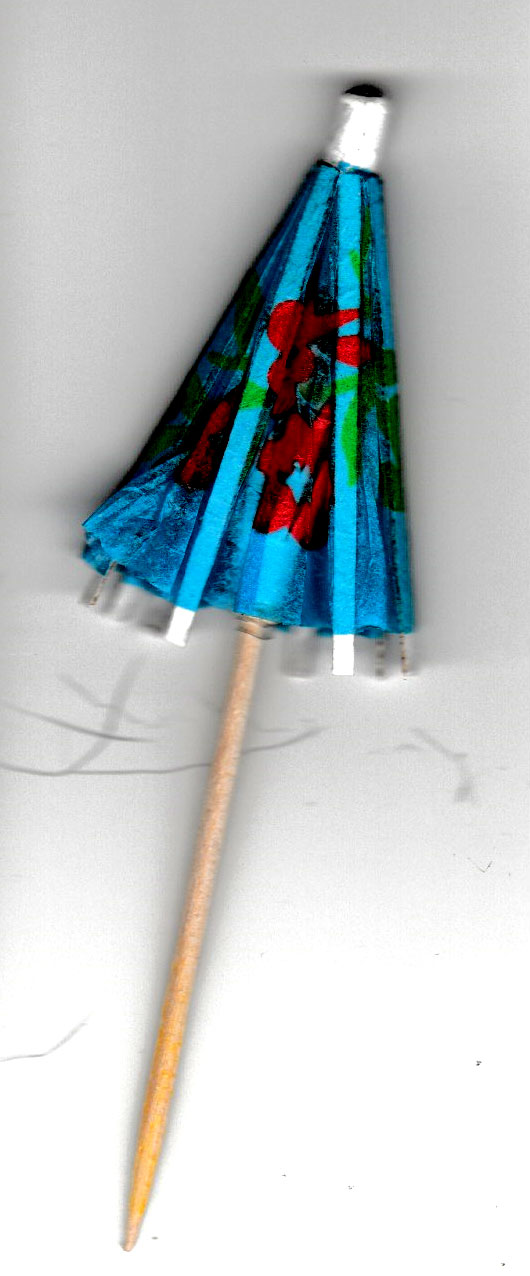

Hey look, these might work! :D

The originals are about 2″ or so in length, if unbent. I’m cutting at 3″ long just because it divides the 12″ rod into 4 equal sticks. Thinking further, I should have cut them at 2″ and gotten 2 spares, but oh well.

The originals are about 2″ or so in length, if unbent. I’m cutting at 3″ long just because it divides the 12″ rod into 4 equal sticks. Thinking further, I should have cut them at 2″ and gotten 2 spares, but oh well.

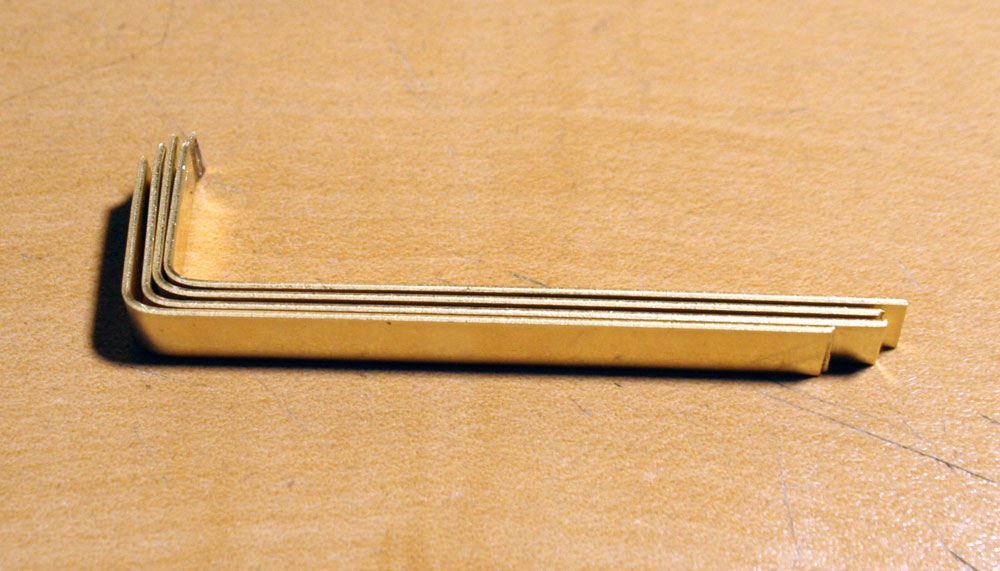

Bend about 1/2″ at a 90 degree angle.

Bend about 1/2″ at a 90 degree angle.  Four new backstops, ready to go. I used the skinnier 1/4″ wide stick rather than the 1/2″ wide one because I figured I’d have to file down the sides a bit on the wider stick, as the originals are .45″ – also the new brass ones are only .032″ thick rather than the original .05″ thick, but that doesn’t matter at all, the new ones are plenty stiff. They work very nicely, and were easy to make from cheap stock ($5 shipped from Amazon for enough to make a dozen or so backstops)

Four new backstops, ready to go. I used the skinnier 1/4″ wide stick rather than the 1/2″ wide one because I figured I’d have to file down the sides a bit on the wider stick, as the originals are .45″ – also the new brass ones are only .032″ thick rather than the original .05″ thick, but that doesn’t matter at all, the new ones are plenty stiff. They work very nicely, and were easy to make from cheap stock ($5 shipped from Amazon for enough to make a dozen or so backstops)

Congrats on the Hummer! And thank you again for the hospitality.

It is *always* a pleasure to have you and the ABQ Crew! (:

*ditto*!

I enjoy your seemingly indefatigable energy! You make the world a much more interesting place! Thanks!

Nice hole puncher.

On my saddle stapler, I use layers of tape to create a guide or what in your case would be a backstop. Surprisingly just enough of an edge to get the paper lined up every time for consistent stapling. I suspect it would work in your case, too. But you found your solution Munk-style. Bravo!

Hi Rev Munk- I have a Wilson Jones Hummer 3 hole punch that is in pretty condition. EXCEPT in order for the punch to operate, I must push down on the hoe punch furthest from the handle for it to work. I have disassembled most of it but cannot find the reason why this happens. Any suggestions?

Possibly the spring inside that furthest tower is broken or misaligned. It can interfere with the punch pin.

Thank you Munk.

Now how do I find 5/16 or larger punch heads? I need min of 3

*shrug* (:

Need larger hole punch, where do I find them” min 5/16. Thanks for the response Munk