Hey, I found my old binder of printers tips and articles from when I was a working offset press operator in the 1990’s. I was delighted to dig this up, as it contains loads of knowledge about paper, inks, printing techniques and terminology that was invaluable back in the day when you could make a good living in that industry.

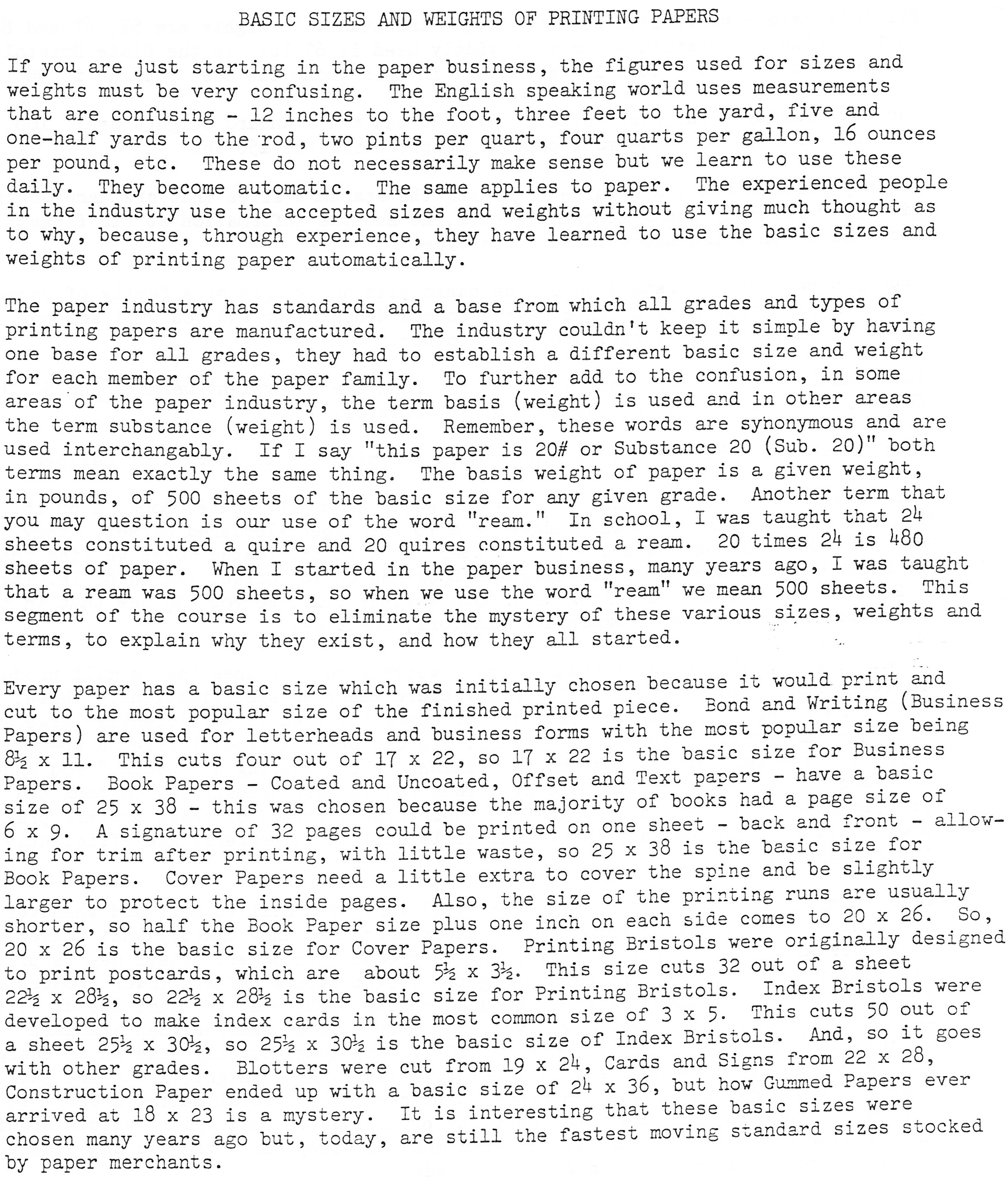

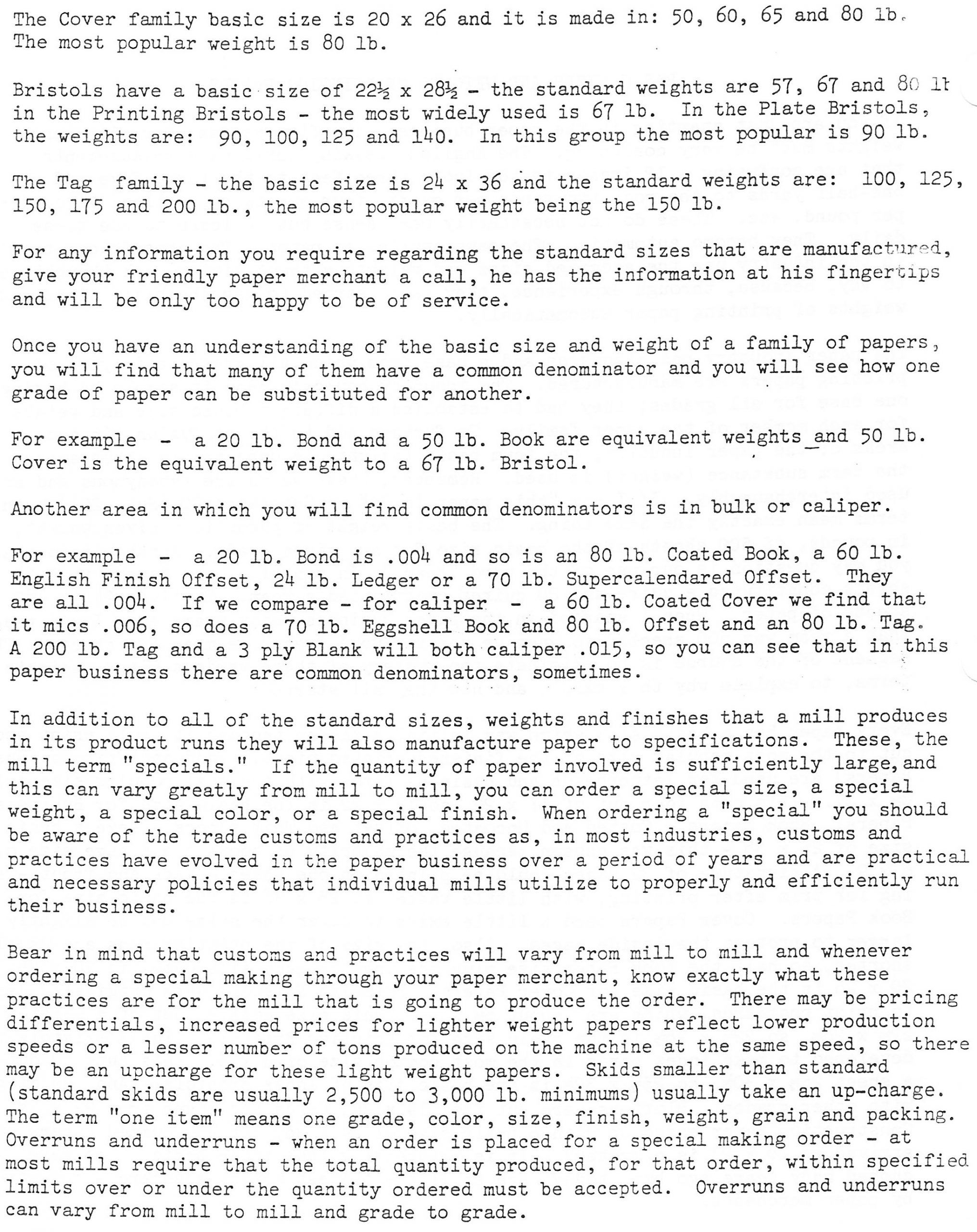

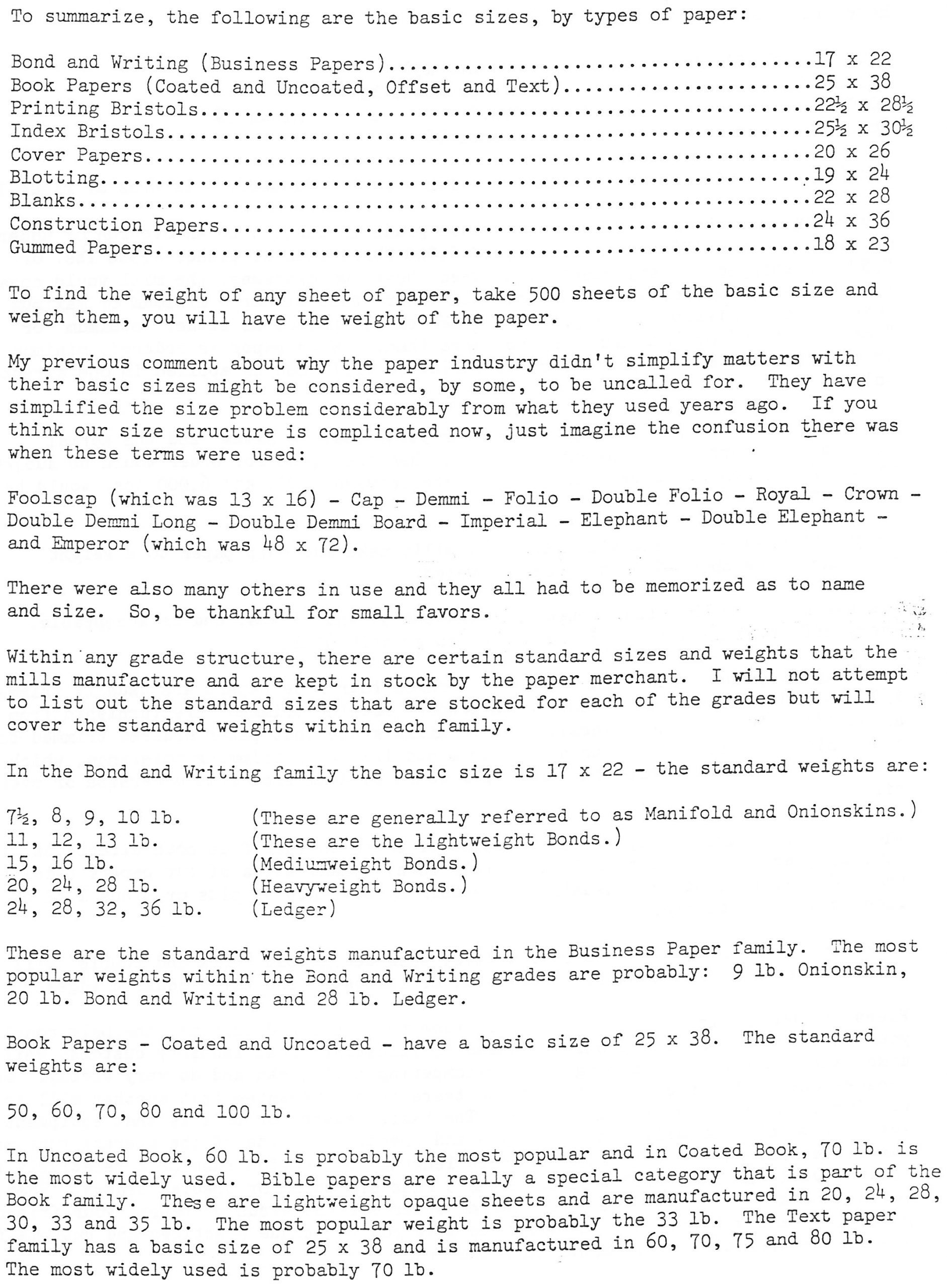

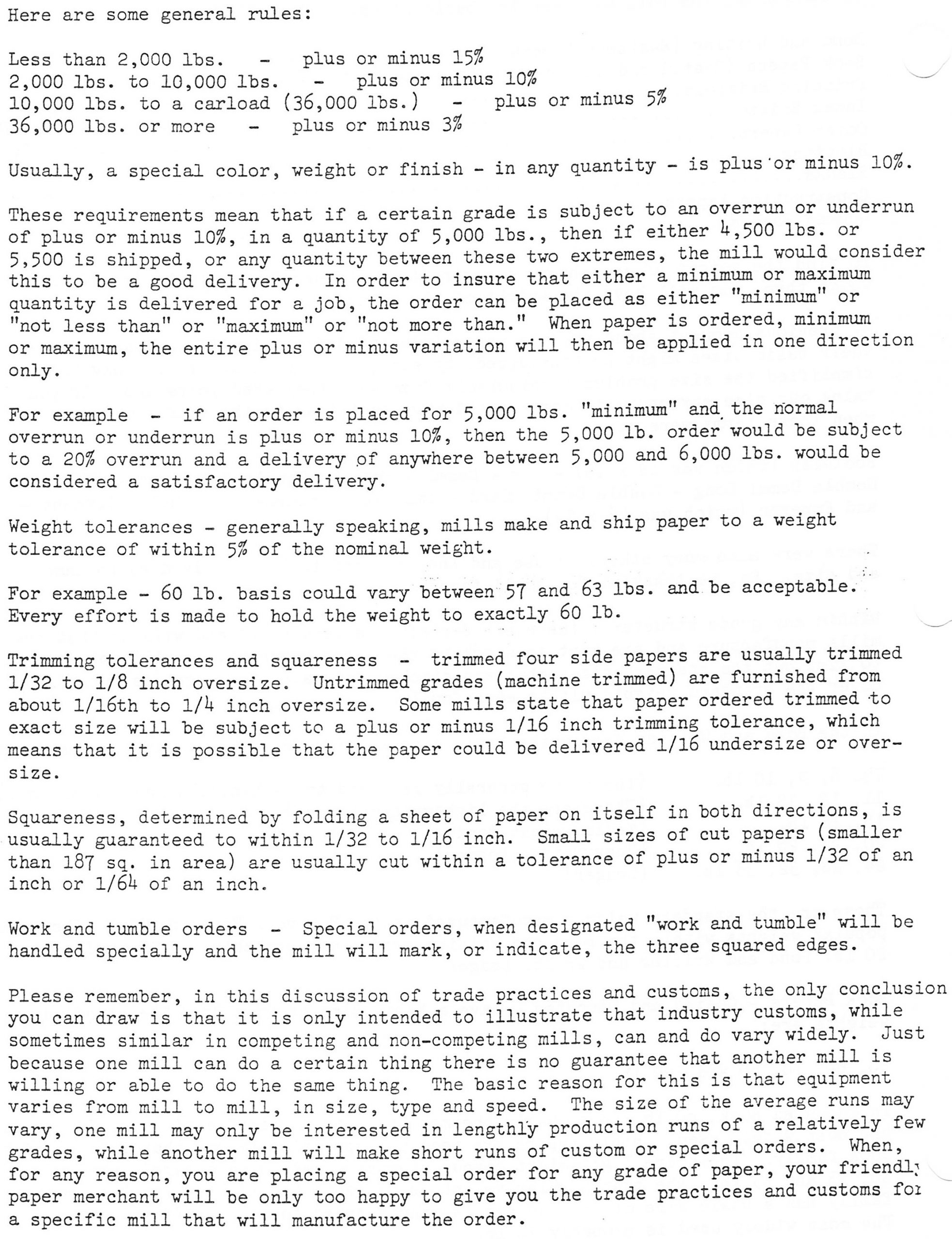

Nowadays, few people really understand the basics of paper manufacture, sizes, weighs, finishes, watermarks, grain, etc, etc, and while I’ve sometimes tried to explain some of these things to my fellow typists from my own rusty memories – I think that posting some of these old articles might be more instructive as to why 24# Linen-finish paper is called that, why 20# Bond and 50# Book are the same thing, and why cutting 11″x17″ paper horizontally in half to make 8.5″x11″ results in a sheet that rolls easier into a typewriter and “feels softer” because you’re converting it from “long grain” to “short grain”.

Heck, if you guys like this series of articles (comment below if you do), I’ll post more, including formulas for calculating various paper-related things, and even some mind-numbingly detailed articles on how certain papers are made. Sound like fun? Let’s start with some basics:

Bravo! More please!

Thanks for this Ted — I dig it (& hope to see more)!

Wow! Interesting post. Yes, please post more.

One of my favorite classes in school was the print shop. Nothing fancy, only a few job presses, but I learned a little about paper, type and font, as well as how to set type. One of my favorite places in town was the local newspaper’s print shop.

Lots of stuff here that I didn’t know. Thanks!

As I’ve mentioned, I briefly worked in the printing industry. In high school, I took an elective class, Graphics Technology, which I absolutely loved. We did typesetting on some sort of typesetting machine that used the 5.25″ inch floppies. (Vague memory there.) We then cut out the text and did layouts on a lightbox using a good ol’ ruler and non-repro blue pencils. Then we took the completed layout and made plates in the darkroom. (LOVED this part. Ah, the smell of chemicals!) Finally, we cranked out the prints on our AB Dick 360’s. I took the class for three semesters, and feeling like a big shot, I landed a job at a local print shop. The interesting thing about the interview for that job, and what specifically ties into your post here, is the fact that the owner would test applicants by asking how many 8.5″ x 11″ sheets you could get out of a parent sheet. If memory serves, the answer was 5. He told me very few of his high school applicants got that part of the interview correct. Sadly, he only put me on the press (also an AB Dick 360) a few times. Then I got stuck in the bindery, proceeding to make all kinds of mistakes. One of the worst was a customer had provided 1,000 sets of NCR forms that just needed numbers added. Well, stupid me, I set the numbering machine incorrectly and screwed up the whole batch. My boss made me call the customer and explain. As a teenager, that was PAINFUL. Ultimately, he was going to have me doing deliveries. He was even going to pay for my driving school. But before that came to fruition, we had a falling out when a family emergency arose. So I typed and mailed my resignation letter. Let’s just say it was “terse”. Oh dear, sorry for the long comment. I’m guessing this is your longest comment ever. Please do continue this series. Fascinating!

erg, bindery mistakes were the worst – you get almost to the finish line and then crash & burn, ruining all that work and worse, the paper cost. O:

I remember them well :P

I’m totally into this. Thanks!