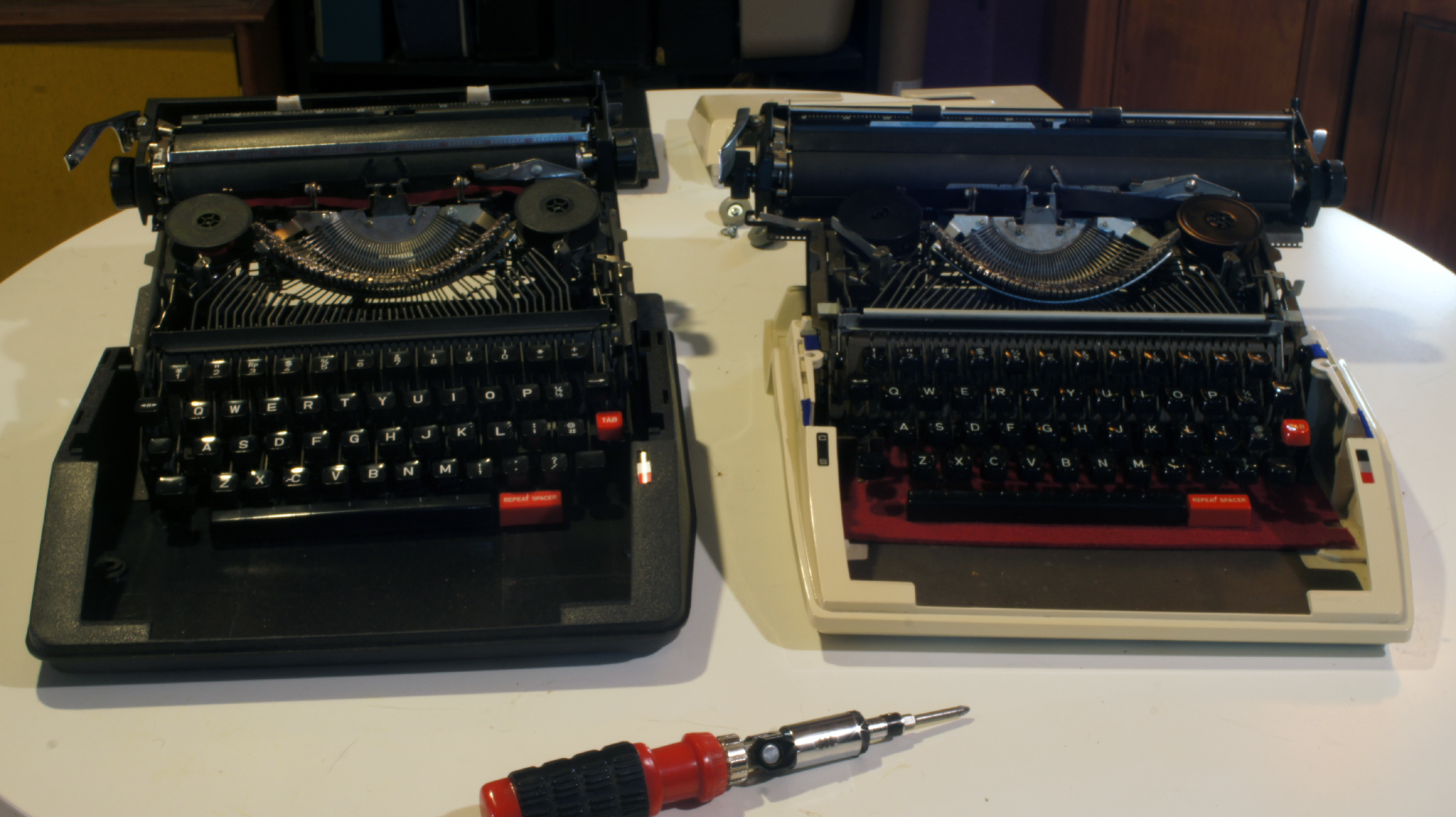

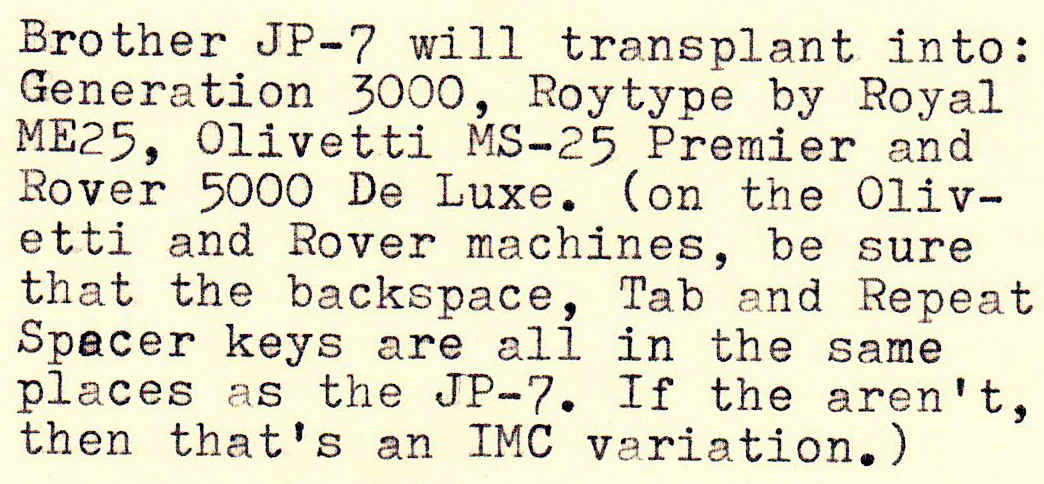

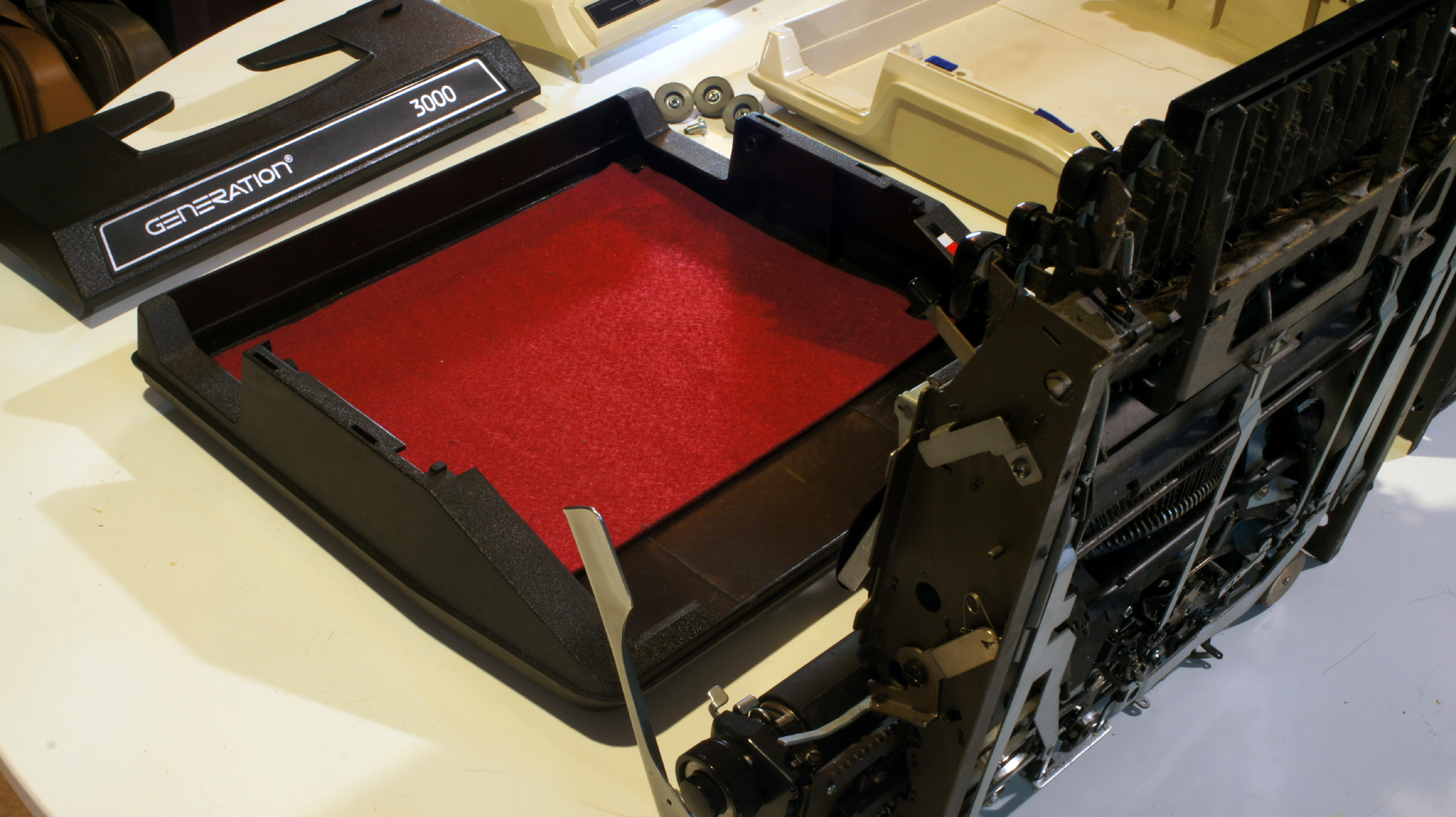

Weapon of Choice: 2006 Generation 3000 with Transplant 1981 JP-7 Engine.

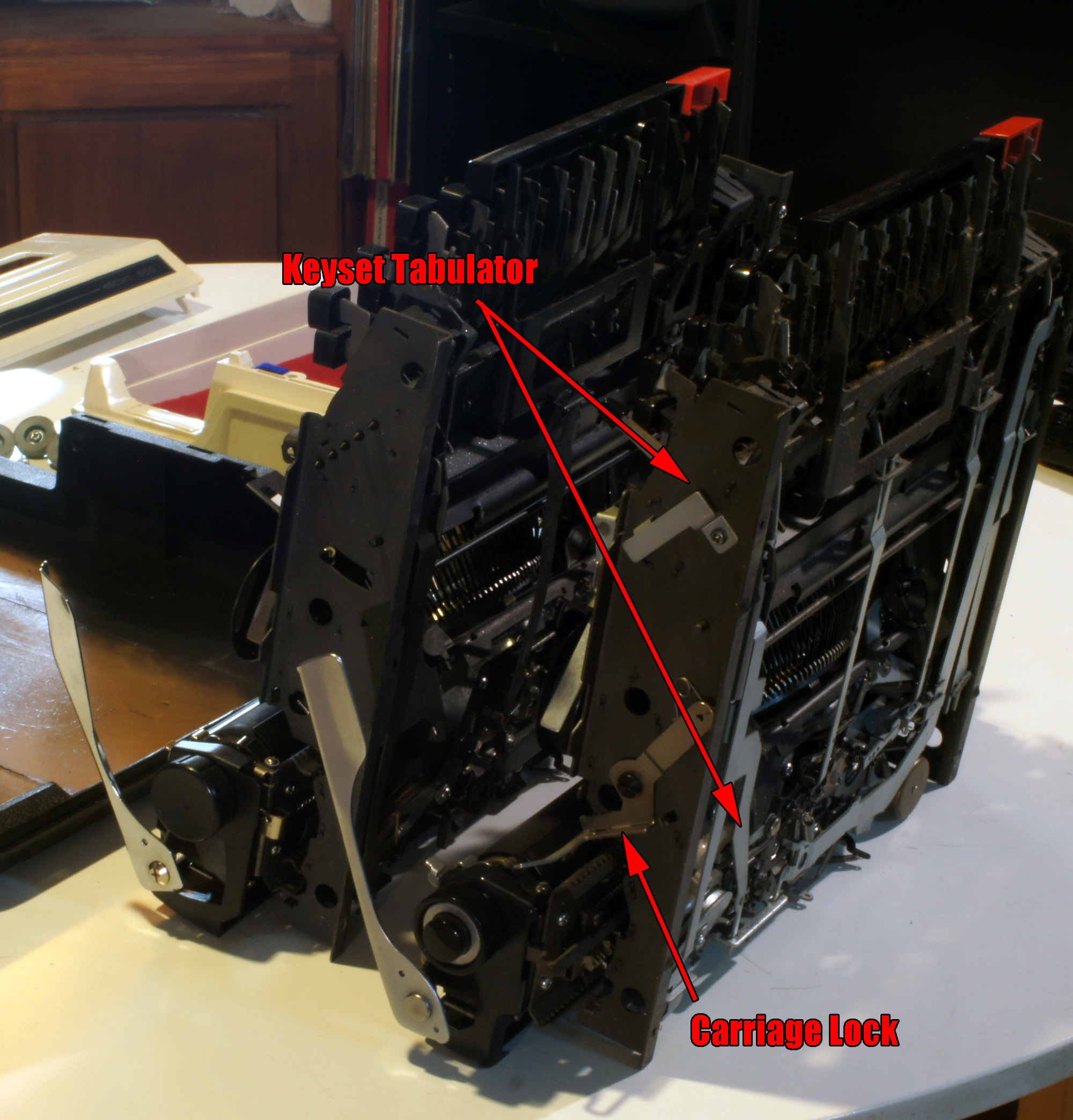

Oddly, the ribbon cover latches are reversed between the two shell designs. You lift up the back on the JP-7, but lift the front on the G3k.

Both shells have 4 screws at the bottom that are removed to take the shell off. the mounting holes are identical.

Once you have removed the 4 screws, just lift the back of the machine and slide out the back, just like a Skyriter.

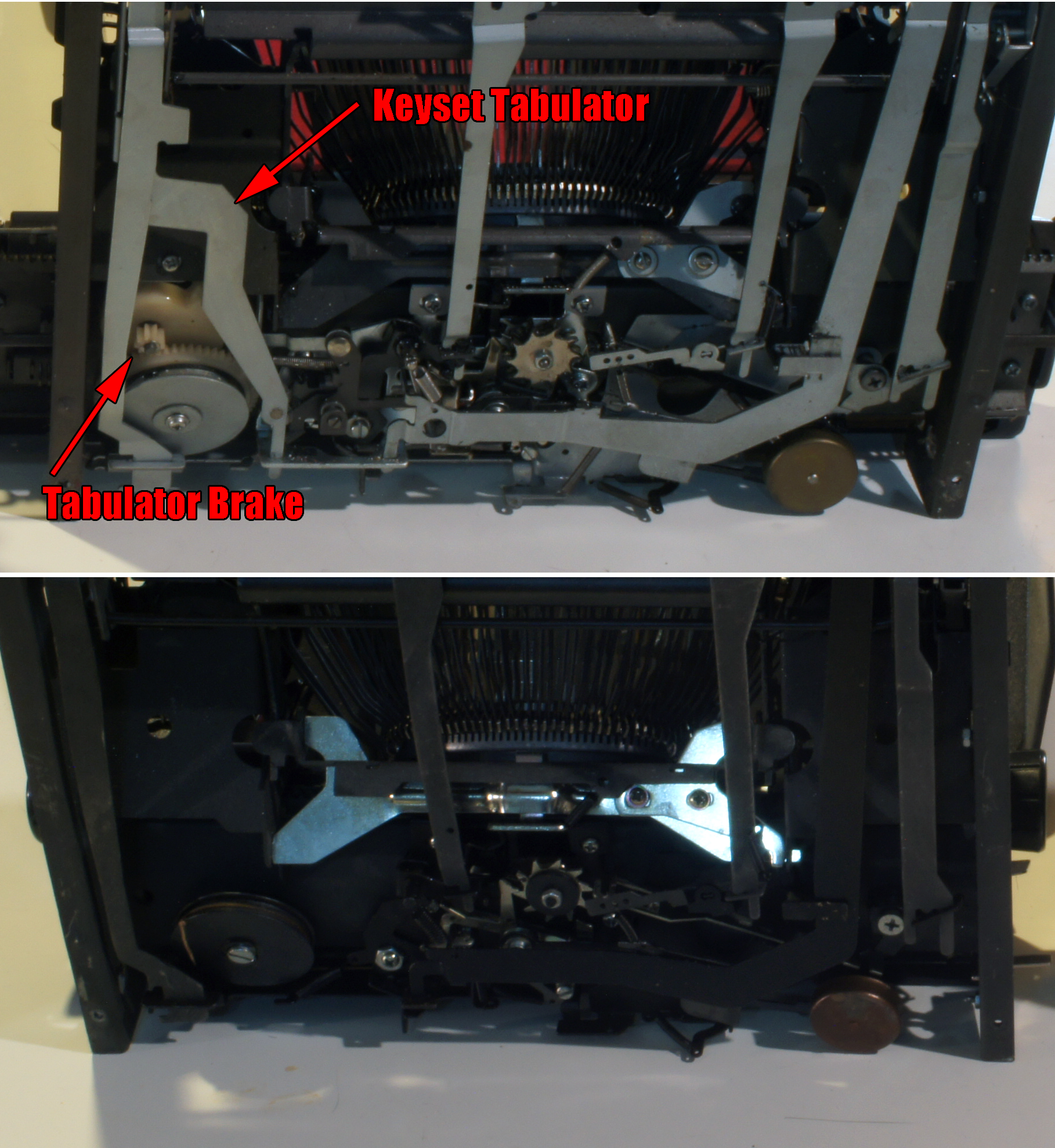

There’s just a few differences between the two machines.

Just a loose felt pad at the bottom helps the noise a lot.

Wow, excellent work, Ted, as usual. Thanks for being so thorough and factual and careful. I wonder if typewriters will ever be so idolized that future scholars will be concerned about original authenticity all the way through, like antique car people, furniture people, and firearm people, or even artworks people. Do you think we should be documenting changes we make away from the original to establish a reliable provenance? I’m sure you don’t; I’m just raising a pedantic question.

You’ve got a lot of gears in my head turning on how to preserve some good old broken plastic body with working mechanics typewriters with a new Chinese plastic body.

Very good work Ted.

How do the two typewriters compare in typing experience? You mentioned that they are very similar mechanically though the 3000 is less fully-featured.

The Chinese guts are much less precise and mushier. On my example the platen detent barely clicks unless I apply finger pressure to the detent spring. It’s pretty clear that the metals used in the chinese machine are very different from the Japanese one, and the build quality is… eh.. not terrible, but not as consistently good as the JP-7. I think the Chinese machine could be adjusted to work well, but I doubt it would stay adjusted for long.

Very interesting experiment.

I agree that 3D-printed shells for old machines are going to come along. I’ve been speculating about that for a while. Take an excellent old mechanism, like an SM9, and put it together with a creative designer and a machine that can produce extraordinary shapes—and you’ve got a fascinating typewriter.

Your experiment also drives home the point that Shanghai Weilv COULD be making good typewriters if they ramped up their quality control, including using durable materials and more precise manufacturing and assembling techniques. Yes, it would cost more, but it might be a smart long-term strategy.

The other thing you’ve got me thinking about is tooling. Why does the SW factory make these particular models? Because they were able to acquire the tooling from the old manufacturers (they even say so: “we bought the typewriter project from OLYMIA [sic] — https://chinatypewriter.en.alibaba.com). Similarly, the tooling for the Princess was sold to the Bulgarians, who produced the OK but inferior Martisa using that design. The tooling for the Brosette went to India, where it became the Jaykay. The tooling for the Barr went to Martin Tytell, who wanted to revive the machine.

If only we had the tooling for the SM9, or the Torpedo 18 ….

Here’s the questions that occur to me:

1) Why is SW producing segment-shifted machines when they (theoretically) have the tooling for the much cheaper to make carriage-shifted Silver-Seiko 700?

2) Why have they acquired the tooling (and theoretically the technical packages) for 4 different machines? Seems like once you have one set, you have all you need for the purposes of building just one main model, and using 4 sets of designs seems like it’d be bad because you’re retraining your assembly workers for every design.

3) where did the Royal A-Frame tooling go after Messa got done with it in the late 80’s?

4) Did Tytell ever do anything with the tooling for the Barr, or is it sitting in some U-Stor-It somewhere?