The ribbon shield installed on the Varityper 110.

The ribbon shield installed on the Varityper 110.

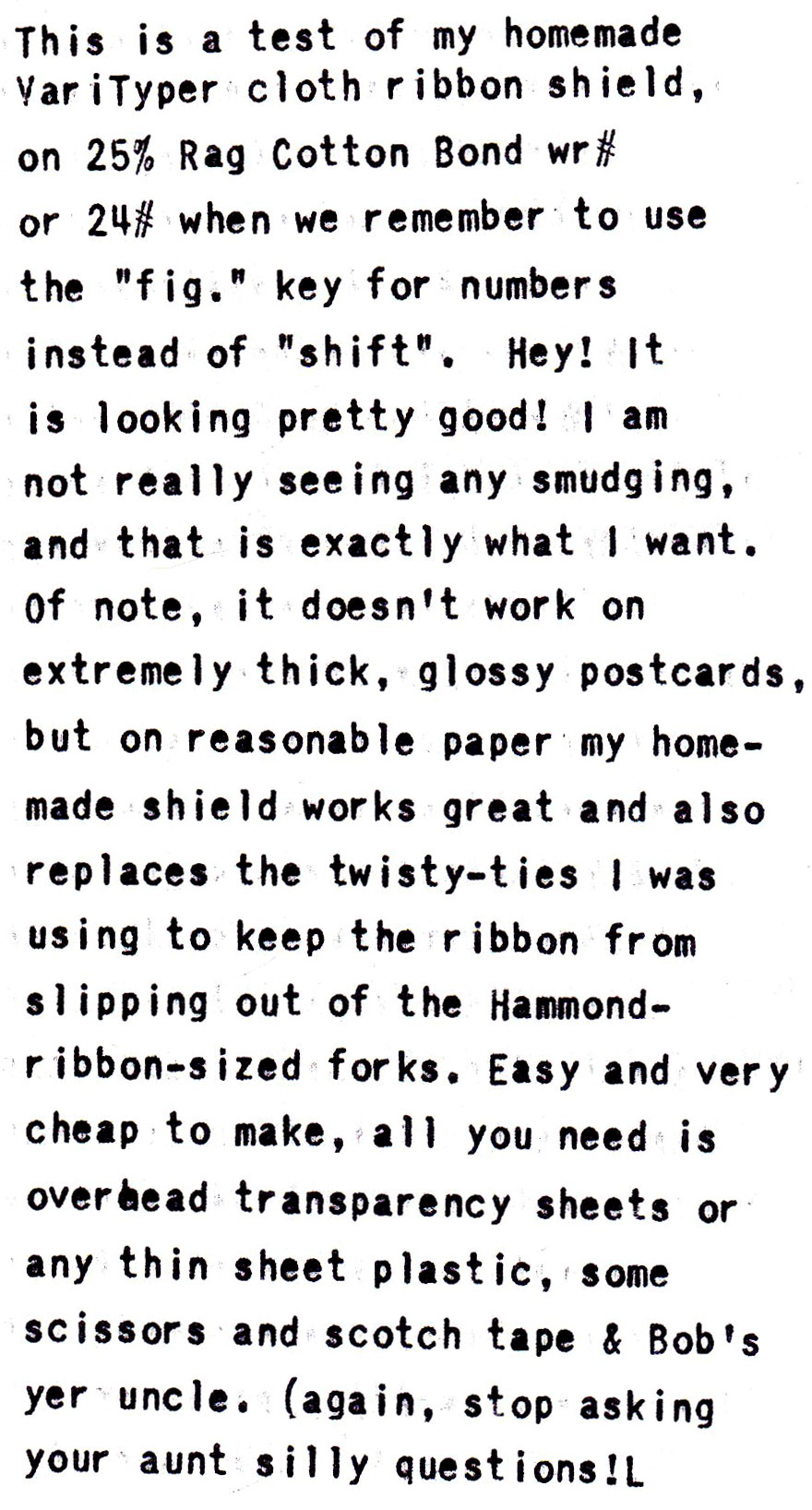

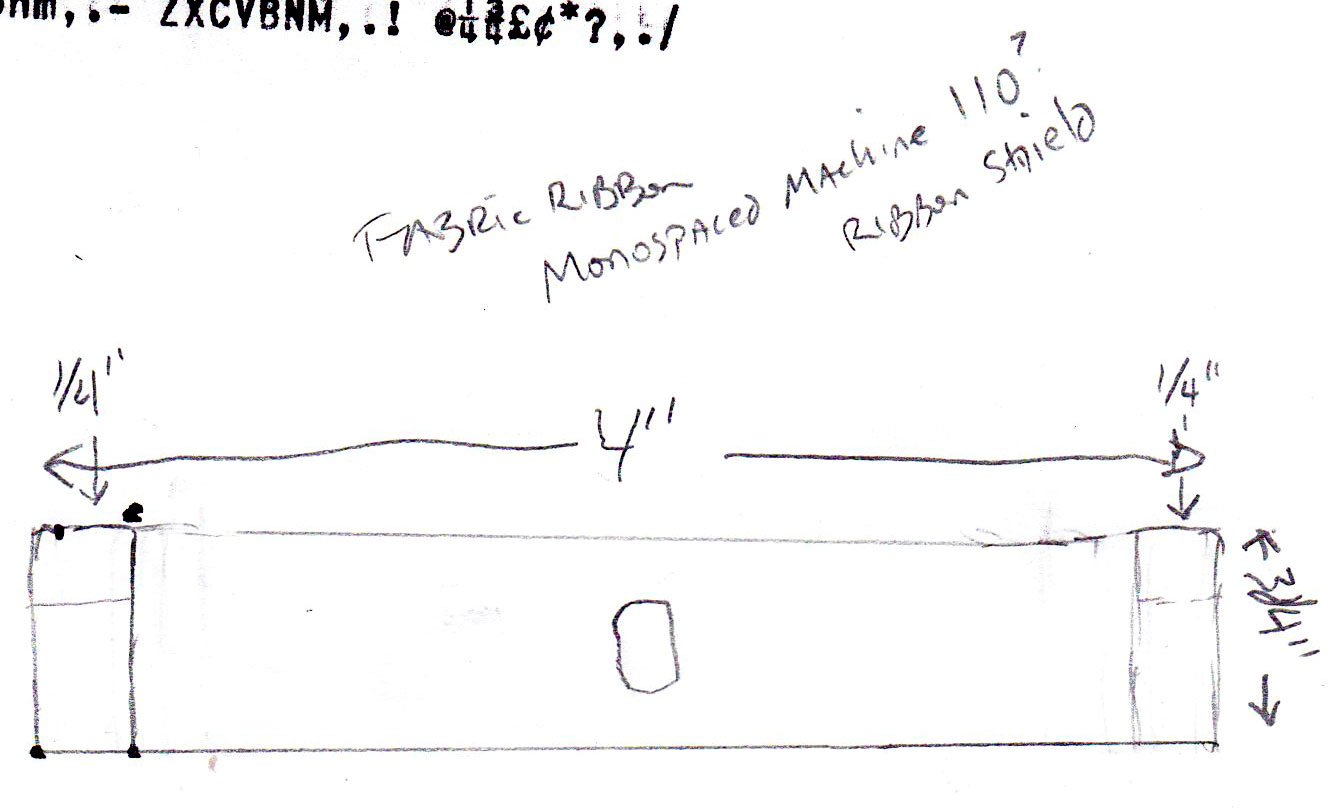

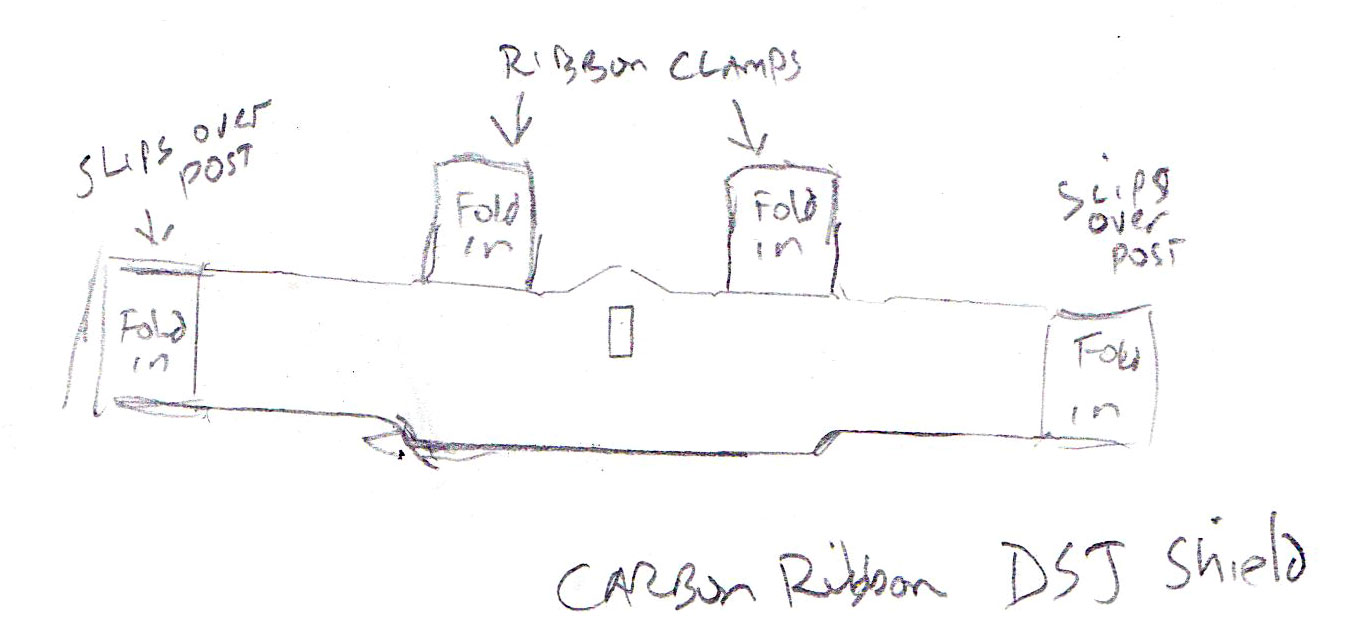

Ribbon shield cut & marked for folding

Ribbon shield cut & marked for folding

I used a hole punch to make the hole the hammer goes through, but if I were to do it right, I’d exactly measure and cut a thinner rectangle that is *just* big enough for the hammer to pass. That would result in absolute smudge protection.

I used a hole punch to make the hole the hammer goes through, but if I were to do it right, I’d exactly measure and cut a thinner rectangle that is *just* big enough for the hammer to pass. That would result in absolute smudge protection.

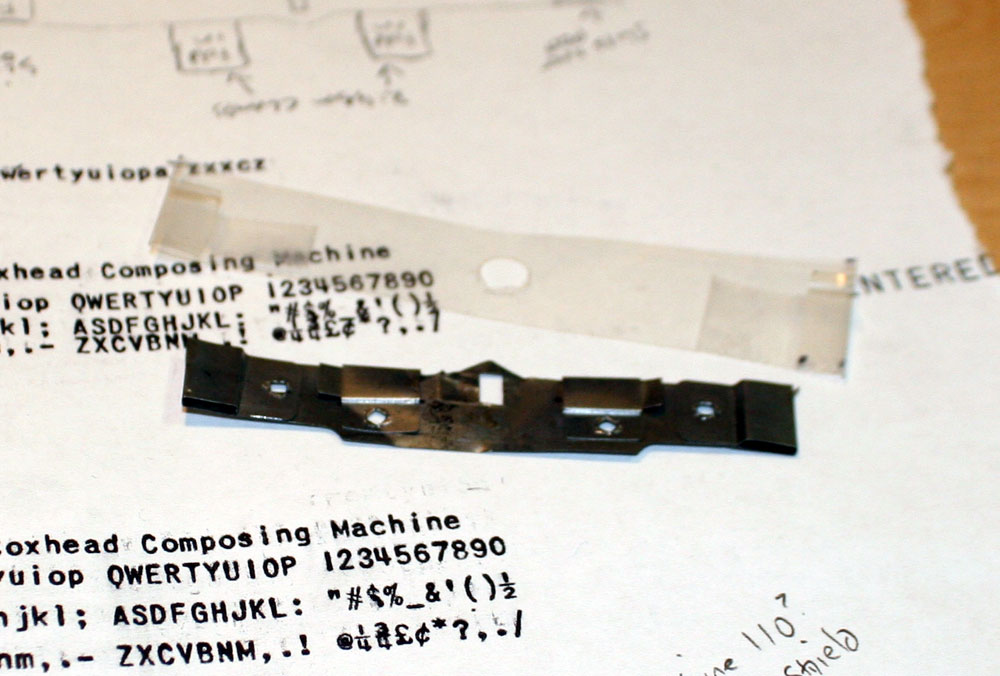

Here’s the thin, stamped steel ribbon shield from the Varityper DSG. It’s kinda banged up, so I straightened it and traced it too in case I need to fabricate a replacement. These were considered to be a consumable for the Hammonds and Varitypers, changed as often as ribbons. Nowadays, Hen’s teeth would be easier to find.

Here’s the thin, stamped steel ribbon shield from the Varityper DSG. It’s kinda banged up, so I straightened it and traced it too in case I need to fabricate a replacement. These were considered to be a consumable for the Hammonds and Varitypers, changed as often as ribbons. Nowadays, Hen’s teeth would be easier to find.

I’d been wondering how the type plate makes a clean impression. I guess it doesn’t without the shield?

Yeah, the width of the shuttle carrier means that the ribbon forks have to be like 3″ apart rather than coming to more of a point like on typebar machines. Without the shield, the paper gets slapped repeatedly onto that strip of ribbon, and if it’s really inky, you get a *lot* of smudging, especially on thicker or clay coated stock.

That certainly did the trick!

Nice work!

Hammonds also used an impression strip. I guess Varitypers don’t.

Huh, not that I know of – it goes hammer slaps paper into ribbon through shield into typeface on shuttle. The shuttle or the hammer could be considered the “platen”, depending on how you look at it. I don’t even know where the impression strip would go on these.